ASTM A403 WP304H Buttweld Pipe Fittings Supplier in India,

Manufacturer of Stainless Steel 304H Pipe Fitting, SS 304H Buttweld Fittings Exporter

Stainless Steel 304H Butt Weld Fittings are designed to be field welded at their ends to join pipes and allow for changes in pipe direction or diameter, or branching or termination. The accessory then becomes part of a system for transporting fluids over short or long distances, safely and efficiently. These ASTM A403 304H Buttweld Fittings are corrosion resistant, have long-term creep efficiency, and have high durable strength. Metalfed Engineering is a renowned manufacturer, supplier, stockist and exporter of SS 304H Buttweld Pipe Fittings in India. We provide top quality products and an efficient after-sales service, which makes us a leading entity in this field, with a wide range of satisfied consumers in the national and international market.

The mechanical properties and chemical composition of this SS 304H Pipe Fittings make it suitable for high temperature, high pressure applications where carbon content is excessively high. In addition Stainless Steel 304H Butt Weld Fittings have an exponential capacity of weldability and formability. The Stainless Steel 304H Butt Weld Fittings are unaffected by weak bases such as ammonium hydroxide, even at high concentrations and high temperatures. The 304H stainless steel elbows are generally very resistant to attack by acids, but this quality depends on the type and concentration of the acid and the ambient temperature. ASTM A403 Gr 304H fittings are standard “18/8” stainless steel; it is the most versatile and widely used stainless steel available in a wider range of products, shapes and finishes than any other. It also has top-quality forming and welding characteristics.

The commonly found industries that use these ASTM A403 Grade WP304H Buttweld Fitting include refineries, chemical industry, marine application, oil and gas, industrial boilers, power plants, pulp and paper industry, nuclear power plants, petrochemicals and many more. Buy Stainless Steel 304H Fittings

from uat best price.

A Specialized Manufacturer of ASTM A403 WP304H Pipe Elbow, UNS S30409 Tee, ASTM A403 Grade WP304H Pipe Bends, Reducer, Stub Ends, ASTM A403 Gr WP304H End Caps, Collar, Pipe Nipple in all Dimensions and Sizes.

- Stainless Steel 304H Pipe Fittings Specifications

- Stainless Steel 304H Pipe Fittings Equivalent Grades

- SS 304H Pipe Fittings Chemical Composition

- Stainless Steel 304H Pipe Fittings Mechanical Properties

- ASTM A403 WP304H Pipe Fittings Size Range

- SS 304H Buttweld Pipe Fittings Manufacturing Standards

- ASTM A403 WP304H Pipe Fittings Dimensional Tolerances

- SS 304H Buttweld Tolerances For Specific Fittings

- ASTM A403 Grade WP304H Buttweld Fittings Alignment Tolerances

- MSS SP-43 SS 304H Buttweld Fittings Dimensions and Tolerances

- Stainless Steel 304H Pipe Fittings Dimensions

- ASTM A403 Gr WP304H Buttweld Fittings Applications

- Stainless Steel 304H Pipe Fittings Exports to

- SS 304H Pipe Fittings Types and Prices

The Stainless Steel 304H Fittings have balanced austenitic structure, which allows for deep drawing without intermediate annealing, making this grade dominate in the manufacture of drawn stainless steel components such as sinks, hollowware, and pans. For these applications, a special variant “304 DDQ” (Depth Drawing Quality) is often used. These fittings can also be easily curbed or rolled into a variety of components for industrial, construction, and transportation applications. Besides having remarkable welding capacity, they also have impressive post-weld annealing characteristics.

- Epoxy Coating

- Electro Polish

- Sand Blasting

- Intergranular Corrosion Test

- Tensile Test

- Hardness Test

- Good load bearing capacity

- Excellent versatility and weldability

- High tensile strength

Stockholder of ASTM A403 WP304H Pipe Fittingts, WERKSTOFF NR. 1.4301 Seamless Pipe Fittings, ASME SA403 SS 304H Welded Pipe Fittings, ASTM A403 WP304H Equal Tee, Stainless Steel 304H Long / Short Radius Elbow at Best Prices in India.

Stainless Steel 304H Buttweld Fittings Specifications

| Product Name: | SS 304H Buttweld Pipe Fittings |

| Specifications: | ASTM A403 WP304H , ASME SA 403 WP304H |

| size range: | Welded Fittings:1/2″ – 48″ Seamless Fittings: 1/2″ – 10″ in Sch 10s, 40s, 80s, 160s, XXS. (DN6~DN100) |

| Dimensions: | ASME/ANSI B16.9, MSS-SP-43, ASME B16.28, BS1560, BS4504, BS4504, BS10 |

| SS 304H Pipe Fittings Types: | Seamless / Welded / Fabricated |

| Thickness: | SCH 10, SCH 20, SCH 30, SCH 40, SCH 60, SCH 80, SCH 100, SCH 120, SCH 140, SCH 160, XS, XXS available with NACE MR 01-75 |

| Bending Radius: | R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom MSS Sp-43 Stainless Steel Pipe Fitting |

| Elbows: | Angle: 22.5 deg, 30 deg, 45 deg, 90 deg, 180 deg, 1D, 1.5D, 2D, 2.5D, 3D, 4D, 5D, 6D, 7D, 8D, 10D-40D. Standard: ASME B16.9, ASME B16.25, ASME B16.28, MSS SP-75 JISB2311 JISB2312 JISB2313, DIN2605 GB, BS, ISO |

| Manufacturing process: | Forge, Cast, Push, Press, etc. |

| Key markets and industries: | Bitumen upgraders. Petrochemicals and acids. Heavy oil refineries. Nuclear power (largely seamless). |

| Test Certificates (TC): | Raw Materials Certificate, EN 10204/3.1B, 100% Radiography Test Report, Third Party Inspection Report, etc |

| Material Test Certificates (MTC): | As per EN 10204 3.1 and EN 10204 3.2, TC certifying NACE MR0103, NACE MR0175 |

| Uses & Application: | SS 304H Pipe Fittings To Connect Pipe & Tubes in Petroleum, Chemical, Power, Gas, Construction, Metallurgy, Shipbuilding. Schedule 10 fittings are an economical alternative for lower-pressure applications. Schedule 40 fittings have a thicker wall for higher-pressure applications. |

ASTM A403 WP304H Buttweld Fittings Equivalent Grades

| Grade | UNS No | Old British | Euronorm | Swedish SS | Japanese JIS | GOST | ||

| BS | En | No | Name | |||||

| SS 304H | S30409 | 304HS31 | 58E | 1.4301 | X5CrNi18-10 | 2332 | SUS 304H | 08Х18Н10 |

SS 304HPipe Fittings Chemical Composition

| Grade | C | Si | Ni | Cr | P | Mn | S | Mo | N | |

| SS 304H | min. | 0.04 | – | 8.0 | 18.0 | – | – | – | – | – |

| max. | 0.10 | 0.75 | 10.5 | 20.0 | 0.045 | 2.0 | 0.030 | |||

ASTM A403 Gr 304H Pipe Fittings Mechanical Properties

| Grade | Tensile Strength (MPa) min | Elongation (% in 50mm) min | Yield Strength 0.2% Proof (MPa) min | Hardness | |

| Rockwell B (HR B) max | Brinell (HB) max | ||||

| SS 304H | 515 | 40 | 205 | 92 | 201 |

Stainless Steel 304H Buttweld Pipe Fittings Size Range

| Below Mentioned SS 304H Pipe Fitting Size: 1/2″ – 48″ | |

| ASTM A403 WP304H SS Elbow – Long Radius | ASTM A403 WP304H SS Stub Ends |

| ASTM A403 Gr WP304H SS Elbow – Short Radius | ASTM A403 WP304H SS Cross |

| ASTM A403 WP304H SS Reducing Elbow | ASTM A403 WP304H SS Reducing Cross |

| ASTM A403 Grade WP304H SS 45° Elbow | ASTM A403 WP304H SS Tees |

| SS ASTM A403 WP304H Fabricated Tee | ASTM A403 WP304H SS End Cap |

| ASTM A403 GR WP304H SS Reducer | ASTM A403 WP304H Coupling |

| ASTM A403 WP304H SS Concentric Reducer | ASTM A403 WP304H SS Pipe Nipple |

| SS ASTM A403 WP304H Eccentric Reducer | ASTM A403 WP304H SS 5D Elbow |

| ASTM A403 WP304H SS 3D Elbow | ASTM A403 WP304H SS Welded Pipe Fittings |

304H Stainless Steel Buttweld Fittings Standards

|

JIS B2311/B2312 Fittings, Japanese Steel Pipe Fittings Standard (All Sizes are welded) This JIS B2311 Fittings Standard specifies the nickel-chromium ferro-alloy seamless pipe fittings and steel and to be fitted by butt-welding , generally pressure service pipings, high pressure service pipings, high pressure service pipings , low temperature service pipings, high temperature service pipings, high temperature service pipings , alloy steel pipings stainless steel pipings, and steel pipes for fired heaters. |

||

| Standard Code | Standard Name | |

| JIS B2311 | JIS B2311 Reducer, Elbow SR JIS B2311 BW, Universal steel butt-welding pipe fittings | |

| JIS B2312 | JIS B2312 Reducer, JIS B2312 Elbow,Steel butt-welding pipe fittings | |

| JIS B2313 | JIS B2313 Fittings, Steel plate butt-welding pipe fittings | |

| Materials | JIS BW fittings are made from materials in accordance with JIS G3452. | |

| Pressure Ratings | JIS B2311/B2312 Buttweld Pipe fittings are free from leakage at hydrostatic pressure up to a maximum of 2.5 MPa. | |

| JIS B2312-82 Fittings Applications | JIS G3452 mostly used for ordinary piping in oil, gas,steam, water, etc at low pressures. | |

| American Steel Pipe Fittings Standard | ||

| ANSI ASME SA-403 | Forged Durimet pipe fittings | |

| ANSI ASME B16.9 | Factory-Made wrought steel pipe fittings | |

| ANSI ASME B16.28 | Wrought steel butt-welding short radius elbows and returns | |

| ISO 5251 | Stainless steel butt-welding fittings | |

| MSS SP-43 | Wrought stainless steel butt-welding fittings | |

| MSS SP-75 | Forging butt-welding fittings | |

| German Steel Pipe Fittings Standard | ||

| DIN 2605 | Steel butt-welding pipe fittings.elbows and bends | |

| DIN 2615 | Steel butt-welding pipe fittings.tees | |

| DIN 2616 | Steel butt-welding pipe fittings.reducers | |

| DIN 2617 | Steel butt-welding pipe fittings.caps | |

| Other Steel Pipe Fittings Standard | ||

| EN 1025 | 3 Butt-welding pipe fittings | |

SS 304H Buttweld Fittings Dimensional Tolerances

Cross-sectional Tolerances for all ASME/ANSI B16.9 and B16.28 Buttwelding Fittings

| Nominal Pipe Size (NPS) | All Fittings | ||||

| OD at Bevel | ID at Bevel ± | Wall thickness | |||

| in | mm | in | mm | ||

| ½ to 2½ | +0.06, -0.03 | +1.6, -0.8 | 0.03 | 0.8 | Not less than 87.5% of nominal wall thickness |

| 3 to 3½ | ±0.6 | ±1.6 | 0.06 | 1.6 | |

| 4 | ±0.6 | ±1.6 | 0.06 | 1.6 | |

| 5 to 6 | +0.09, -0.06 | +2.4, -1.6 | 0.06 | 1.6 | |

| 8 | +0.09, -0.06 | +2.4, -1.6 | 0.06 | 1.6 | |

| 10 | +0.16, -0.12 | +4.0, -3.2 | 0.12 | 3.2 | |

| 12 to 18 | +0.16, -0.12 | +4.0, -3.2 | 0.12 | 3.2 | |

| 20 to 24 | +0.25, -0.19 | +6.4, -4.8 | 0.19 | 4.8 | |

| 26 to 30 | +0.25, -0.19 | +6.4, -4.8 | 0.19 | 4.8 | |

| 32 to 48 | +0.25, -0.19 | +6.4, -4.8 | 0.19 | 4.8 | |

Stainless Steel 304H Buttweld Tolerances for Specific Buttweld Fittings

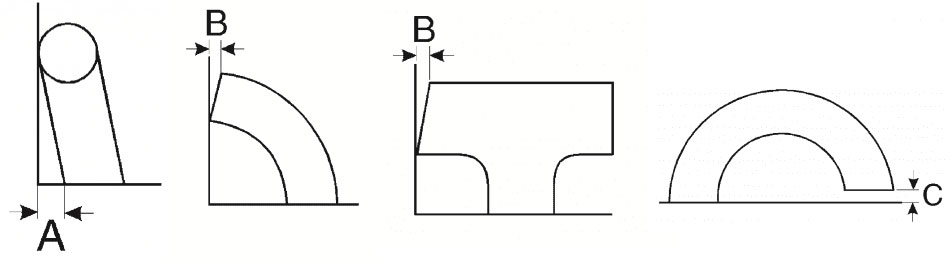

Stainless Steel 304H Dimensional Tolerances for ASME/ANSI B16.9 & B16.28 Elbows and Returns

| Nominal Pipe Size (NPS) | 90° & 45° Long Radius Elbows 90° Short Radius Elbows and Tees |

180° Returns | ||||

| Centre-to-End Dimension ± A, B |

Centre-to-Centre Dimension ± B (=2 x A) |

Back-to-Face Dimension ± C |

||||

| in | mm | in | mm | in | mm | |

| ½ to 2½ | 0.06 | 2 | 0.25 | 6 | 0.25 | 6 |

| 3 to 3½ | 0.06 | 2 | 0.25 | 6 | 0.25 | 6 |

| 4 | 0.06 | 2 | 0.25 | 6 | 0.25 | 6 |

| 5 to 6 | 0.06 | 2 | 0.25 | 6 | 0.25 | 6 |

| 8 | 0.06 | 2 | 0.25 | 6 | 0.25 | 6 |

| 10 | 0.09 | 2 | 0.38 | 10 | 0.25 | 6 |

| 12 to 18 | 0.09 | 2 | 0.38 | 10 | 0.25 | 6 |

| 20 to 24 | 0.09 | 2 | 0.38 | 10 | 0.25 | 6 |

| 26 to 30 | 0.12 | 3 | – | – | – | – |

| 32 to 48 | 0.19 | 5 | – | – | – | – |

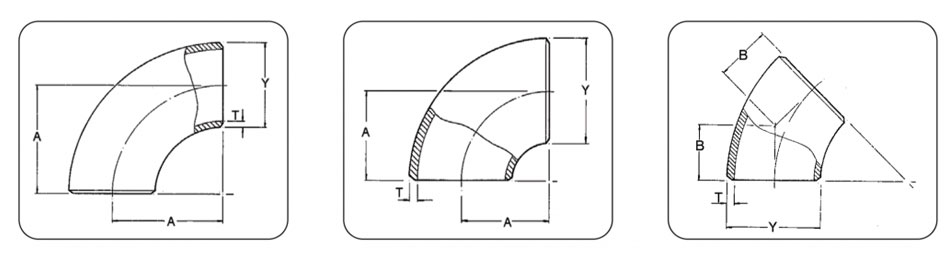

Stainless Steel 304H Buttweld Fittings Dimensional Tolerances for ASME/ANSI B16.9 Reducers, Caps and Stub Ends

| Nominal Pipe Size (NPS) | Reducers & Lap Joint Stub Ends |

Caps | Lap Joint Stub Ends | |||||

| Overall Length ± A |

Overall Length ± A |

OD of Lap B |

Fillet Radius of Lap B |

|||||

| in | mm | in | mm | in | mm | in | mm | |

| ½ to 2½ | 0.06 | 2 | 0.12 | 3 | +0 | +0, -1 | +0 | +0, -1 |

| 3 to 3½ | 0.06 | 2 | 0.12 | 3 | +0, -0.03 | +0, -1 | +0, -0.03 | +0, -1 |

| 4 | 0.06 | 2 | 0.12 | 3 | +0, -0.03 | +0, -1 | +0, -0.06 | +0, -2 |

| 5 to 6 | 0.06 | 2 | 0.25 | 6 | +0, -0.03 | +0, -1 | +0, -0.06 | +0, -2 |

| 8 | 0.06 | 2 | 0.25 | 6 | +0, -0.03 | +0, -1 | +0, -0.06 | +0, -2 |

| 10 | 0.09 | 2 | 0.25 | 6 | +0, -0.06 | +0, -2 | +0, -0.06 | +0, -2 |

| 12 to 18 | 0.09 | 2 | 0.25 | 6 | +0, -0.06 | +0, -2 | +0, -0.06 | +0, -2 |

| 20 to 24 | 0.09 | 2 | 0.25 | 6 | +0, -0.06 | +0, -2 | +0, -0.06 | +0, -2 |

| 26 to 30 | 0.19 | 5 | 0.38 | 10 | – | – | – | – |

| 32 to 48 | 0.19 | 5 | 0.38 | 10 | – | – | – | – |

Stainless Steel 304H Buttweld Fittings Alignment Tolerances

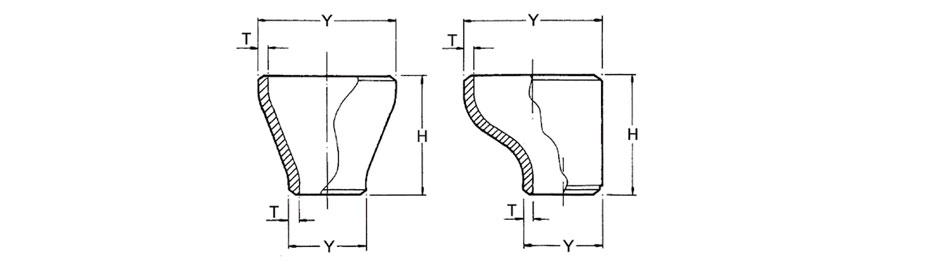

Alignment tolerances are concerned with the way that the ends of a fitting are cut. Exaggerated distortions are shown for clarity in the diagram above.

SS ASTM A403 WP304H Buttweld Pipe Fittings Alignment Tolerances (ASME/ANSI B16.9)

| Nominal Pipe Size (NPS) | Off Plane Tolerances, ± A |

Off Angle Tolerances, ± B |

Alignment of Ends, ± C |

|||

| in | mm | in | mm | in | mm | |

| ½ to 4 | 0.06 | 2 | 0.03 | 1 | 0.03 | 1 |

| 5 to 8 | 0.12 | 4 | 0.06 | 2 | 0.03 | 1 |

| 10 to 12 | 0.19 | 5 | 0.09 | 2 | 0.06 | 2 |

| 14 to 16 | 0.25 | 6 | 0.09 | 3 | 0.06 | 2 |

| 18 to 24 | 0.38 | 10 | 0.12 | 4 | 0.06 | 2 |

| 26 to 30 | 0.38 | 10 | 0.19 | 5 | – | – |

| 32 to 42 | 0.50 | 13 | 0.19 | 5 | – | – |

| 44 to 48 | 0.75 | 19 | 0.19 | 5 | – | – |

Dimensions and Tolerances of ASTM A403 WP304H Stainless Steel Pipe Fittings (MSS SP-43)

The tolerances and dimensions defined in MSS SP-43 are substantially the same as defined in ASME/ANSI specifications (½ to 24 in). MSS SP-43 only covers ss 304H Buttweld fittings made for use with Schedule 10S and 5S pipe as defined in ANSI/ASME B36.19M also it covers short pattern stub ends suitable for use with Schedule 40S pipe.

- MSS SP-43 tolerances are the same as for ASME/ANSI B16.9 and B16.28 except with regard to the outside diameter at the bevel:

- Tolerance of OD at Bevel =

- ± 0.03 in for NPS ½ to 4

- +0.06, -0.03 in for NPS 5 to 8

- +0.09, -0.03 in for NPS 10 to 18

- +0.12, to -0.03 in for NPS 20 to 24

ASTM A403 Grade WP304H Buttweld Fittings Dimensions

Dimensions and weights of ASME B16.9 Stainless Steel 304H Buttweld 45 Degree Elbow, 90 Degree Elbows Short and Long Radius (NPS 1/2 to 24, schedule STD/XS)

| Pipe Elbow Nominal Size | Pipe Elbow Outside Diameter Y |

Wall Thickness T (Pipe Elbow Schedule) |

45 Deg. Elbow LR Centre to Face B | 45 Deg. Elbow LR Weight |

90 Deg. Elbow LR Centre to Face A | 90 Deg. Elbow LR Weight | 90 Deg. Elbow SR Centre to Face A | 90 Deg. Elbow SR Weight | ||

| mm | in | mm | mm | Schedule | mm | kg | mm | kg | mm | kg |

| 15 | 1/2” | 21.3 | 2.78 | STD | 15.9 | 0.04 | 38.1 | 0.08 | – | – |

| 3.73 | X.S | 15.9 | 0.05 | 38.1 | 0.10 | – | – | |||

| 20 | 3/4” | 26.7 | 2.87 | STD | 11.1 | 0.04 | 28.6 | 0.08 | – | – |

| 3.91 | X.S | 11.1 | 0.05 | 28.6 | 0.11 | – | – | |||

| 25 | 1” | 33.4 | 3.38 | STD | 22.2 | 0.09 | 38.1 | 0.15 | 25.4 | 0.11 |

| 4.55 | X.S | 22.2 | 0.11 | 38.1 | 0.19 | 25.4 | 0.14 | |||

| 32 | 11/4” | 42.2 | 3.56 | STD | 25.4 | 0.14 | 47.6 | 0.28 | 31.75 | 0.18 |

| 4.85 | X.S | 25.4 | 0.2 | 47.6 | 0.39 | 31.75 | 0.24 | |||

| 40 | 11/2” | 48.3 | 3.68 | STD | 28.6 | 0.2 | 57.1 | 0.4 | 38.1 | 0.26 |

| 5.08 | X.S | 28.6 | 0.25 | 57.1 | 0.5 | 38.1 | 0.35 | |||

| 50 | 2” | 60.3 | 3.91 | STD | 34.9 | 0.36 | 76.2 | 0.72 | 50.8 | 0.5 |

| 5.54 | X.S | 34.9 | 0.5 | 76.2 | 1.0 | 50.8 | 0.68 | |||

| 65 | 21/2” | 73.0 | 5.16 | STD | 44.4 | 0.73 | 95.2 | 1.46 | 63.5 | 0.95 |

| 7.01 | X.S | 44.4 | 0.91 | 95.2 | 1.82 | 63.5 | 1.27 | |||

| 80 | 3” | 88.9 | 5.49 | STD | 50.8 | 1.1 | 114.3 | 2.18 | 76.2 | 1.45 |

| 7.62 | X.S | 50.8 | 1.45 | 114.3 | 2.86 | 76.2 | 1.95 | |||

| 100 | 4” | 114.3 | 6.02 | STD | 63.5 | 2.1 | 152.4 | 4.2 | 101.6 | 2.8 |

| 8.56 | X.S | 63.5 | 2.9 | 152.4 | 5.7 | 101.6 | 3.9 | |||

| 125 | 5” | 141.3 | 6.65 | STD | 79.4 | 3.4 | 190.0 | 6.8 | 127.0 | 4.8 |

| 9.5 | X.S | 79.4 | 5.0 | 190.0 | 10.0 | 127.0 | 6.5 | |||

| 150 | 6” | 168.3 | 7.11 | STD | 95.2 | 5.1 | 229.0 | 10.1 | 152.4 | 6.8 |

| 10.97 | X.S | 95.2 | 7.7 | 229.0 | 15.3 | 152.4 | 10.2 | |||

| 200 | 8” | 219.1 | 8.18 | STD | 127.0 | 10.2 | 305.0 | 20.4 | 203.0 | 13.6 |

| 12.7 | X.S | 127.0 | 15.5 | 305.0 | 30.9 | 203.0 | 20.9 | |||

| 250 | 10” | 273.9 | 9.27 | STD | 159.0 | 18.1 | 381.0 | 36.1 | 254.0 | 24.1 |

| 12.7 | X.S | 159.0 | 24.4 | 381.0 | 48.8 | 254.0 | 32.5 | |||

| 300 | 12” | 323.9 | 9.52 | STD | 190.0 | 26.6 | 457.0 | 53.1 | 305.0 | 35.4 |

| 12.7 | X.S | 190.0 | 35.0 | 457.0 | 70.0 | 305.0 | 46.7 | |||

| 350 | 14” | 355.6 | 9.52 | STD | 222.0 | 34.1 | 533.0 | 68.1 | 356.0 | 45.4 |

| 12.7 | X.S | 222.0 | 45.0 | 533.0 | 90.0 | 356.0 | 60.0 | |||

| 400 | 16” | 406.4 | 9.52 | STD | 254.0 | 45.0 | 610.0 | 89.3 | 406.0 | 59.5 |

| 12.7 | X.S | 254.0 | 59.0 | 610.0 | 118.0 | 406.0 | 78.7 | |||

| 450 | 18” | 457.0 | 9.52 | STD | 286.0 | 56.5 | 686.0 | 113.0 | 457.0 | 75.6 |

| 12.7 | X.S | 286.0 | 75.0 | 686.0 | 150.0 | 457.0 | 100.0 | |||

| 500 | 20” | 508.0 | 9.52 | STD | 318.0 | 85.0 | 762.0 | 140.0 | 508.0 | 93.5 |

| 12.7 | X.S | 318.0 | 112.5 | 762.0 | 186.0 | 508.0 | 124.0 | |||

| 600 | 24” | 610.00 | 9.52 | STD | 381.0 | 101.5 | 914.0 | 203.0 | 610.0 | 135.0 |

| 12.7 | X.S | 381.0 | 134.5 | 914.0 | 269.0 | 610.0 | 179.0 | |||

Dimensions and weights of ASME B16.9 Stainless Steel 304H Buttweld Tee and Cap (NPS 1/2 to 24, schedule STD/XS)

| Buttweld Tee and Cap Nominal Size |

Pipe Tee and Cap Outside Diameter Y |

Pipe Tee and Cap Wall Thickness T |

Buttweld Tee Dimensions (C and M) |

Buttweld Tee Weight |

Buttweld Cap End to End |

Buttweld Cap Weight |

||

| mm | in | mm | mm | Schedule | mm | mm | mm | kg |

| 15 | 1/2” | 21.3 | 2.78 | STD | 25.4 | 0.58 | ||

| 3.73 | X.S | 25.4 | 0.21 | |||||

| 20 | 3/4” | 26.7 | 2.87 | STD | 28.6 | 0.21 | ||

| 3.91 | X.S | 28.6 | 0.27 | |||||

| 25 | 1” | 33.4 | 3.38 | STD | 38.1 | 0.34 | 38.1 | 0.1 |

| 4.55 | X.S | 38.1 | 0.43 | 38.1 | 0.14 | |||

| 32 | 11/4” | 42.2 | 3.56 | STD | 47.6 | 0.64 | 38.1 | 0.14 |

| 4.85 | X.S | 47.6 | 0.75 | 38.1 | 0.18 | |||

| 40 | 11/2” | 48.3 | 3.68 | STD | 57.1 | 0.95 | 38.1 | 0.18 |

| 5.08 | X.S | 57.1 | 1.13 | 38.1 | 0.23 | |||

| 50 | 2” | 60.3 | 3.91 | STD | 63.5 | 1.45 | 38.1 | 0.27 |

| 5.54 | X.S | 63.5 | 1.72 | 38.1 | 0.32 | |||

| 65 | 21/2” | 73.0 | 5.16 | STD | 76.2 | 2.45 | 38.1 | 0.41 |

| 7.01 | X.S | 76.2 | 2.95 | 38.1 | 0.45 | |||

| 80 | 3” | 88.9 | 5.49 | STD | 85.7 | 3.45 | 50.8 | 0.64 |

| 7.62 | X.S | 85.7 | 4.3 | 50.8 | 0.82 | |||

| 100 | 4” | 114.3 | 6.02 | STD | 105.0 | 5.7 | 63.5 | 1.13 |

| 8.56 | X.S | 105.0 | 7.3 | 63.5 | 1.54 | |||

| 125 | 5” | 141.3 | 6.65 | STD | 124.0 | 9.1 | 76.2 | 1.91 |

| 9.5 | X.S | 124.0 | 11.8 | 76.2 | 2.59 | |||

| 150 | 6” | 168.3 | 7.11 | STD | 143.0 | 13.6 | 88.9 | 2.95 |

| 10.97 | X.S | 143.0 | 19.0 | 88.9 | 4.1 | |||

| 200 | 8” | 219.1 | 8.18 | STD | 178.0 | 25.0 | 101.6 | 5.0 |

| 12.7 | X.S | 178.0 | 33.5 | 101.6 | 7.3 | |||

| 250 | 10” | 273.0 | 9.27 | STD | 216.0 | 41.0 | 127.0 | 9.1 |

| 12.7 | X.S | 216.0 | 54.0 | 127.0 | 12.0 | |||

| 300 | 12” | 323.9 | 9.52 | STD | 254.0 | 57.0 | 152.4 | 13.6 |

| 12.7 | X.S | 254.0 | 77.0 | 152.4 | 17.0 | |||

| 350 | 14” | 355.6 | 9.52 | STD | 279.0 | 73.0 | 165.1 | 15.9 |

| 12.7 | X.S | 279.0 | 93.0 | 165.1 | 21.0 | |||

| 400 | 16” | 406.4 | 9.52 | STD | 305.0 | 91.0 | 178.8 | 20.0 |

| 12.7 | X.S | 305.0 | 120.0 | 178.8 | 26.0 | |||

| 450 | 18” | 457.0 | 9.52 | STD | 343.0 | 127.0 | 203.2 | 26.0 |

| 12.7 | X.S | 343.0 | 165.0 | 203.2 | 34.0 | |||

| 500 | 20” | 508.0 | 9.52 | STD | 381.0 | 227.0 | 228.6 | 33.0 |

| 12.7 | X.S | 381.0 | 270.0 | 228.6 | 43.0 | |||

| 600 | 24” | 610.0 | 9.52 | STD | 432.0 | 345.0 | 266.7 | 46.0 |

| 12.7 | X.S | 432.0 | 430.0 | 266.7 | 61.0 | |||

Dimensions and Weights of ASME B16.9 Stainless Steel 304H Buttweld Concentric Reduce rs and Eccentric Reducers(NPS 1/2 to 24, schedule STD/XS)

| Buttweld Reducer Nominal Size |

Pipe Reducer Length H | Pipe Reducer Schedule T | Pipe Reducer Weight |

|

| mm | in | mm | Kg | |

| 20×15 | 3/4” x 1/2” | 38.1 | STD | 0.07 |

| XS | 0.1 | |||

| 25×15 | 1” x 1/2” | 50.8 | STD | 0.14 |

| X.S | 0.18 | |||

| 25×20 | 1” x 3/4” | 50.8 | STD | 0.14 |

| X.S | 0.18 | |||

| 32×15 | 11/4” x 1/2” | 50.8 | STD | 0.18 |

| X.S | 0.23 | |||

| 32×20 | 11/4” x 3/4“ | 50.8 | STD | 0.18 |

| X.S | 0.23 | |||

| 32×25 | 11/4” x 1” | 50.8 | STD | 0.18 |

| X.S | 0.23 | |||

| 40×15 | 11/2” x 1/2” | 63.5 | STD | 0.27 |

| X.S | 0.32 | |||

| 40×20 | 11/2” x 3/4” | 63.5 | STD | 0.27 |

| X.S | 0.32 | |||

| 40×25 | 11/2” x 1” | 63.5 | STD | 0.27 |

| X.S | 0.32 | |||

| 40×32 | 11/2” x 11/4” | 63.5 | STD | 0.27 |

| X.S | 0.32 | |||

| 50×15 | 2” x 1/2” | 76.2 | STD | 0.41 |

| X.S | 0.54 | |||

| 50×20 | 2” x 3/4” | 76.2 | STD | 0.41 |

| X.S | 0.54 | |||

| 50×25 | 2”x1” | 76.2 | STD | 0.41 |

| X.S | 0.54 | |||

| 50×32 | 2” x 11/4” | 76.2 | STD | 0.41 |

| X.S | 0.54 | |||

| 50×40 | 2” x 11/2” | 76.2 | STD | 0.41 |

| X.S | 0.54 | |||

| 65×25 | 21/2” x 1” | 88.9 | STD | 0.68 |

| X.S | 0.91 | |||

| 65×32 | 21/2” x 11/4” | 88.9 | STD | 0.68 |

| X.S | 0.91 | |||

| 65×40 | 21/2” x 11/2” | 88.9 | STD | 0.68 |

| X.S | 0.91 | |||

| 65×50 | 21/2” x 2” | 88.9 | STD | 0.68 |

| X.S | 0.91 | |||

| 80×40 | 3” x 11/2” | 88.9 | STD | 0.77 |

| X.S | 1.09 | |||

| 80×50 | 3”x2” | 88.9 | STD | 0.91 |

| X.S | 1.22 | |||

| 80×65 | 3” x 21/2” | 88.9 | STD | 0.91 |

| X.S | 1.27 | |||

| 100×40 | 4” x 11/2” | 101.6 | STD | 1.36 |

| X.S | 1.91 | |||

| 100×50 | 4”x2” | 101.6 | STD | 1.40 |

| X.S | 1.95 | |||

| 100×65 | 4” x 21/2” | 101.6 | STD | 1.45 |

| X.S | 2.04 | |||

| 100×80 | 4”x3” | 101.6 | STD | 1.59 |

| X.S | 2.08 | |||

| 125×80 | 5”x3” | 127.0 | STD | 2.5 |

| X.S | 3.4 | |||

| 125 x 100 | 5”x4” | 127.0 | STD | 2.7 |

| X.S | 3.8 | |||

| 150×50 | 6”x2” | 140.0 | STD | 3.4 |

| X.S | 4.3 | |||

| 150×65 | 6” x 21/2” | 140.0 | STD | 3.4 |

| X.S | 4.5 | |||

| 150×80 | 6”x3” | 140.0 | STD | 3.6 |

| X.S | 4.8 | |||

| 150 x 100 | 6”x4” | 140.0 | STD | 3.7 |

| X.S | 5.2 | |||

| 150 x 125 | 6”x5” | 140.0 | STD | 3.9 |

| X.S | 5.4 | |||

| 200×80 | 8”x3” | 152.4 | STD | 4.5 |

| X.S | 7.2 | |||

| 200 x 100 | 8”x4” | 152.4 | STD | 5.0 |

| X.S | 7.7 | |||

| 200 x 125 | 8”x5” | 152.4 | STD | 5.4 |

| X.S | 8.2 | |||

| 200 x 150 | 8”x6” | 152.4 | STD | 5.9 |

| X.S | 8.6 | |||

| 250 x 100 | 10”x4” | 178.0 | STD | 9.1 |

| X.S | 11.8 | |||

| 250 x 125 | 10”x5” | 178.0 | STD | 9.5 |

| X.S | 13.6 | |||

| 250 x 150 | 10”x6” | 178.0 | STD | 9.5 |

| X.S | 13.6 | |||

| 250 x 200 | 10”x8” | 178.0 | STD | 10.0 |

| X.S | 14.0 | |||

| 300 x 150 | 12”x6” | 203.0 | STD | 14.1 |

| X.S | 18.1 | |||

| 300 x 200 | 12”x8” | 203.0 | STD | 14.5 |

| X.S | 19.1 | |||

| 300 x 250 | 12” x 10” | 203.0 | STD | 15.4 |

| X.S | 20.0 | |||

| 350 x 200 | 14”x8” | 330.0 | STD | 26.3 |

| X.S | 34.9 | |||

| 350 x 250 | 14” x 10” | 330.0 | STD | 27.2 |

| X.S | 36.3 | |||

| 350 x 300 | 14” x 12” | 330.0 | STD | 28.6 |

| X.S | 37.6 | |||

| 400 x 200 | 16”x8” | 356.0 | STD | 31.8 |

| X.S | 42.6 | |||

| 400 x 250 | 16” x 10” | 356.0 | STD | 33.1 |

| X.S | 43.5 | |||

| 400 x 300 | 16” x 12” | 356.0 | STD | 34.5 |

| X.S | 45.4 | |||

| 400 x 350 | 16” x 14” | 356.0 | STD | 35.4 |

| X.S | 46.3 | |||

| 450 x 250 | 18” x 10” | 381.0 | STD | 38.0 |

| X.S | 52.1 | |||

| 450 x 300 | 18” x 12” | 381.0 | STD | 39.0 |

| X.S | 53.5 | |||

| 450 x 350 | 18” x 14” | 381.0 | STD | 40.0 |

| X.S | 54.9 | |||

| 450 x 400 | 18” x 16” | 381.0 | STD | 40.8 |

| X.S | 53.5 | |||

| 500 x 250 | 20” x 10” | 508.0 | STD | 53.0 |

| X.S | 79.9 | |||

| 500 x 300 | 20” x 12” | 508.0 | STD | 54.4 |

| X.S | 82.0 | |||

| 500 x 350 | 20” x 14” | 508.0 | STD | 57.6 |

| X.S | 80.2 | |||

| 500 x 400 | 20” x 16” | 508.0 | STD | 58.9 |

| X.S | 82.0 | |||

| 500 x 450 | 20” x 18” | 508.0 | STD | 61.7 |

| X.S | 82.0 | |||

| 600 x 300 | 24” x 12” | 508.0 | STD | 63.5 |

| X.S | 84.4 | |||

| 600 x 350 | 24” x 14” | 508.0 | STD | 65.3 |

| X.S | 86.8 | |||

| 600 x 400 | 24” x 16” | 508.0 | STD | 68.0 |

| X.S | 90.4 | |||

| 600 x 450 | 24” x 18” | 508.0 | STD | 72.6 |

| X.S | 96.5 | |||

| 600 x 500 | 24” x 20” | 508.0 | STD | 77.1 |

| X.S | 102.5 | |||

Stainless Steel 304H Buttweld Fittings Types

90 Degree Elbow

Stainless Steel 304H 90 Degree Elbow

Price: $600.00-$1,000.00 / Ton

45 Degree Elbow

Stainless Steel 304H 45 Degree Elbow

Price: $10-$60 / Kilogram

180 Degree Elbow

Stainless Steel 304H 180 Degree Elbow

Price: $1-$40.00 / Piece

1D / 1.5D Elbow

Stainless Steel 304H 1D/1.5D Elbow / Bends

Price: $20-$40.00 / Piece

3D / 5D Elbow

Stainless Steel 304H 3D/5D Elbow / Bends

Price: $600.00-$1,000.00 / Ton

Equal Tee

Stainless Steel 304H Equal Tee

Price: $500.00-$1200.00 / Ton

Unequal Tee / Reducing Tee

Stainless Steel 304H Unequal or Reducing Tee

Price: $10-$60.00 / Kilogram

Lateral Tee

Stainless Steel 304H Lateral Tee

Price: $400.00-$900.00 / Ton

Long Radius Pipe Bend

Stainless Steel 304H Long Radius Pipe Bend

Price: $10-$100.00 / Kilogram

Split Tee

Stainless Steel 304H Split Tee

Price: $200.00-$1200.00 / Ton

Concentric Reducer

Stainless Steel 304H Concentric Reducer

Price: $500.00-$1,000.00 / Ton

Eccentric Reducer

Stainless Steel 304H Eccentric Reducer

Price: $400.00-$1300.00 / Ton

Equal Cross

Stainless Steel 304H Equal Cross

Price: $10-$40.00 / Piece

Unequal Cross

Stainless Steel 304H Unequal Cross

Price: $600.00-$1,000.00 / Ton

Lap Joint Stub End

Stainless Steel 304H Lap Joint Stub End

Price: $700.00-$1400.00 / Ton

End Cap/ Pipe Cap

Stainless Steel 304H Pipe End Caps

Price: $30-$80.00 / Kilogram

Piggable Bend

Stainless Steel 304H Piggable Bend

Price: $600.00-$1,000.00 / Ton

Hot Induction Pipe Bend

Stainless Steel 304H Hot Induction Pipe Bend

Price: $10-$40.00 / Piece

J PipeBend

Stainless Steel 304H J Pipe Bend

Price: $20-$90.00 / Kilogram

Mitered Pipe Bend

Stainless Steel 304H Mitered Pipe Bend

Price: $600.00-$1,000.00 / Ton

U Pipe Bend

Stainless Steel 304H U Pipe Bend

Price: $10-$40.00 / Piece

3D Pipe Bend

Stainless Steel 304H 3D Pipe Bend

Price: $30-$80.00 / Kilogram

5D Pipe Bend

Stainless Steel 304H 5D Pipe Bend

Price: $600.00-$1,000.00 / Ton

8D Pipe Bend

Stainless Steel 304H 8D Pipe Bend

Price: $10-$40.00 / Piece

10D Pipe Bend

Stainless Steel 304H 10D Pipe Bend

Price: $30-$80.00 / Kilogram

IBR Approved Buttweld Fittings

Stainless Steel 304H IBR Approved Fittings

Price: $600.00-$1,000.00 / Ton

Hub and Clamp Connector Fittings

Stainless Steel 304H Hub and Clamp Connector Fittings

Price: $300-$800 / Ton

Note: Prices are based on product, material grade and quantity. Contact us anytime to get full quotation.

ASTM A403 SS 304H Buttweld Pipe Fittings – Applications & Industries

We are well-known prestigious Manufacturers, Exporters, and Suppliers of high quality Stainless Steel 304H Buttweld Pipe Fittings. We supply ANSI B16.9 SS 304H Pipe Fittings to customers in various industries including chemical, pharmaceutical, petrochemical, power, engineering and various other industrial applications. Test Certificate as per EN 10204 / 3.1B, Raw Materials Certificate, Third Party Inspection Report and 100% Radiography Test Report.

Ready Stock of 304H Stainless Steel Pipe Fittings Export to

Africa Algeria, Angola, Benin, Botswana, Burkina Faso, Burundi, Cabo Verde, Cameroon, Central African Republic (CAR), Chad, Comoros, The Democratic Republic of the Congo, Republic of the Congo, Cote d’Ivoire, Djibouti, Egypt, Equatorial Guinea, Eritrea, Ethiopia, Gabon, Gambia, Ghana, Guinea, Guinea-Bissau, Kenya, Lesotho, Liberia, Libya, Madagascar, Malawi, Mali, Mauritania, Mauritius, Morocco, Mozambique, Namibia, Niger, Nigeria, Rwanda, Sao Tome and Principe, Senegal, Seychelles, Sierra Leone, Somalia, South Africa, South Sudan, Sudan, Swaziland, Tanzania, Togo, Tunisia, Uganda, Zambia, Zimbabwe

Europe,Albania, Finland, France, Ireland, Italy, Andorra, Armenia, Austria, Bosnia and Herzegovina, Bulgaria, Croatia, Cyprus, Czech Republic, Georgia, Germany, Denmark, Estonia, Kazakhstan, Kosovo, Greece, Hungary, Iceland, Latvia, Liechtenstein, Azerbaijan, Belarus, Belgium, Lithuania, Luxembourg, Macedonia, Malta, Moldova, Monaco, Montenegro, Netherlands, Norway, Poland, Portugal, Romania, Russia, San Marino, Serbia, Slovakia, Slovenia, Spain, Sweden, Turkey, Ukraine, United Kingdom, Vatican City

AmericaAntigua and Barbuda, Bahamas, Barbados, Belize, Canada, Costa Rica, Cuba, Dominica, Dominican Republic, El Salvador, Grenada, Guatemala, Haiti, Honduras, Jamaica, Mexico, Nicaragua, Panama, Saint Kitts and Nevis, Saint Lucia, Saint Vincent and the Grenadines, Trinidad and Tobago, United States of America, Argentina, Bolivia, Brazil, Chile, Colombia, Ecuador, Guyana, Paraguay, Peru, Suriname, Uruguay, Venezuela

Asia/OceaniaAfghanistan, Armenia, Azerbaijan, Bahrain, Bangladesh, Bhutan, Brunei, Cambodia, China, Cyprus, Georgia, India, Indonesia, Iran, Iraq, Israel, Japan, Jordan, Laos, Lebanon, Malaysia, Maldives, Mongolia, Myanmar (Burma), Oman, Pakistan, Palestine, Philippines, Qatar, Nepal, North Korea, Russia, Saudi Arabia, Singapore, South Korea, Sri Lanka, Syria, Taiwan, Tajikistan, Thailand, Timor-Leste, Turkey, Turkmenistan, United Arab Emirates (UAE), Uzbekistan, Vietnam, Yemen, Australia, Fiji, Kiribati, Marshall Islands, Micronesia, Nauru, New Zealand, Palau, Papua New Guinea, Samoa, Solomon Islands, Tonga, Tuvalu, Vanuatu

Please send us the complete details of Stainless Steel 304H Buttweld Pipe Fittings requirement. We offer SS 304H Pipe Fittings, and ASTM A403 WP304H Buttweld Pipe Fittings which are accurately designed to provide satisfaction to our customers. We have a team of highly skilled professionals, who support us in all our career activities right from a realization of raw material to testing and final dispatch of these SS 304H Buttweld Elbow, Tee, ASTM A403 WP304H Reducer, Bend, Cross, ASTM A403 WP304H End Caps, Stub Ends, Coller, Pipe Nipple at our valuable customers end.

sales@metalfed.com | +91 9137898594 | Quotation Form | Reach Us

Venezuela

Venezuela Myanmar

Myanmar Sri Lanka

Sri Lanka Belgium

Belgium Czechia

Czechia Greece

Greece Mexico

Mexico Tobago

Tobago Brazil

Brazil Chile

Chile France

France Colombia

Colombia South Africa

South Africa Jordan

Jordan Spain

Spain Hong Kong

Hong Kong Netherlands

Netherlands Poland

Poland Bangladesh

Bangladesh Indonesia

Indonesia Taiwan

Taiwan Nigeria

Nigeria Iraq

Iraq Ukraine

Ukraine Romania

Romania Cyprus

Cyprus Angola

Angola Norway

Norway USA

USA Saudi Arabia

Saudi Arabia Kuwait

Kuwait Thailand

Thailand South Korea

South Korea Singapore

Singapore Malaysia

Malaysia UAE

UAE Germany

Germany Italy

Italy Costa Rica

Costa Rica Kazakhstan

Kazakhstan Philippines

Philippines China

China UK

UK India

India Japan

Japan Russia

Russia Canada

Canada Iran

Iran Turkey

Turkey Morocco

Morocco Egypt

Egypt Vietnam

Vietnam Oman

Oman Australia

Australia Qatar

Qatar Portugal

Portugal