Leading Manufacturers, Suppliers, and Exporters of Carbon Steel Fittings and Flanges in Argentina, Chile, Kazakhstan, Zambia

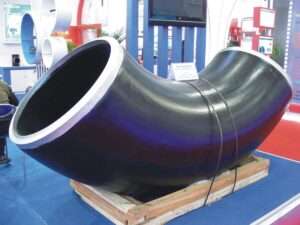

Leading Manufacturers, Suppliers, and Exporters of Carbon Steel Fittings and Flanges in Argentina, Chile, Kazakhstan, Zambia: Let us tell you first about Metalfed Engineering and later we discuss Everything About Carbon Steel Fittings and Flanges. We are leading Manufacturers, Suppliers, and Exporters of Carbon Steel Elbow, Tee, Reducers, Cross, Pipe Bends, Coupling, End Cap, Union, Boss, Nipple, Adapters, Plugs, Bushings, Street Elbow, Weld Neck Flanges, Blind Flanges, Slip-on Flanges, and Threaded Flanges.

We are Suppliers and Exporters of Industrial Fittings and Flanges in Argentina, Chile, Kazakhstan, and Zambia.

Carbon steel is an iron-carbon alloy, which contains up to 2.1 wt.% carbon of the steel’s total weight, and is one of the primary categories of steel. It makes up as much as 90% of steel manufactured globally. Carbon Steel can be categorized into 5 sub-categories as Ultra-low-carbon steels, Extra-low-carbon steels, Low-carbon steels, Medium-carbon steels, and High-carbon steels.

- High-carbon: a carbon content over 0.5%.

- Medium-carbon: between 0.2% and 0.49% carbon.

- Low-carbon: between 0.05% and 0.19% carbon.

- Extra-low-carbon: between 0.015% and 0.05% carbon.

- Ultra-low-carbon: carbon content less than 0.015%.

- Carbon Steel Pipe Fittings Equivalent Grades

- Carbon Steel Pipe Fittings Chemical Composition

- Carbon Steel Pipe Fittings Mechanical Properties

- Carbon Steel Pipe Fittings Dimensional Tolerances

- MSS SP-43 Buttweld Fittings Dimensions and Tolerances

- Carbon Steel Pipe Fittings Dimensions

- Carbon Steel Forged Fittings Chemical Composition

- Carbon Steel Forged Fittings Mechanical Properties

- Carbon Steel Forged Fittings Dimensions

- Carbon Steel Forged Fittings Weight Chart

- Carbon Steel Flanges Chemical Composition

- ASTM A350 Carbon Steel Flanges Mechanical Properties

- ASTM A105 Carbon Steel PN16 Flange Dimensions

- Carbon Steel Blind Flange Weight Chart

- ASTM A105 Flange Pressure Ratings

Leading Manufacturers, Suppliers, and Exporters of Carbon Steel Fittings and Flanges in Argentina, Chile, Kazakhstan, Zambia

Carbon Steel Fittings and Flanges Production Range

| Product Name: | ASTM A234 WPB Pipe Fittings | ASTM A420 WPL6 & WPL3 Pipe Fittings | ASTM A860 Pipe Fittings |

| Specifications: | ASME SA234, ASME SA420, ASME SA860 |

| size: | Welded Butt Weld Fittings:1/2″ – 48″ Seamless Butt Weld Fittings: 1/2″ – 10″ in Sch 10s, 40s, 80s, 160s, XXS. (DN6~DN100) |

| Dimensions: | ASME/ANSI B16.9, MSS-SP-43, ASME B16.28, BS1560, BS4504, BS4504, BS10 |

| Types: | Seamless / Welded / Fabricated |

| Thickness: | SCH 10, SCH 20, SCH 30, SCH 40, SCH 60, SCH 80, SCH 100, SCH 120, SCH 140, SCH 160, XS, XXS available with NACE MR 01-75 |

| Bending Radius: | R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom MSS Sp-43 Carbon Steel Pipe Fitting |

| Elbows: | Angle: 22.5 deg, 30 deg, 45 deg, 90 deg, 180 deg, 1D, 1.5D, 2D, 2.5D, 3D, 4D, 5D, 6D, 7D, 8D, 10D-40D. Standard: ASME B16.9, ASME B16.25, ASME B16.28, MSS SP-75 JISB2311 JISB2312 JISB2313, DIN2605 GB, BS, ISO |

| Manufacturing process: | Forge, Cast, Push, Press, etc. |

| Key markets and industries: | Bitumen upgraders. Petrochemicals and acids. Heavy oil refineries. Nuclear power (largely seamless). |

| Test Certificates (TC): | Raw Materials Certificate, EN 10204/3.1B, 100% Radiography Test Report, Third Party Inspection Report, etc |

| Material Test Certificates (MTC): | As per EN 10204 3.1 and EN 10204 3.2, TC certifying NACE MR0103, NACE MR0175 |

| Uses & Application: | Fittings To Connect Pipe & Tubes in Petroleum, Chemical, Power, Gas, Construction, Metallurgy, Shipbuilding. Schedule 10 fittings are an economical alternative for lower-pressure applications. Schedule 40 fittings have a thicker wall for higher-pressure applications. |

| Product Name: | Carbon A105 Forged Fittings | Low Temperature Carbon Steel A350 LF2 High Pressure Forged Fittings | High Yield Carbon Steel Forged Fittings |

| Specifications: | ASTM A105/ ASME SA105, ASTM A350/ ASME SA350, ASTM A694 / ASME SA694 |

| Size: | 1/8” NB to 4” NB (Socketweld & Screwed-Threaded) |

| Dimensions: | ASME 16.11, MSS SP-79, 83, 95, 97, BS 3799 |

| Pressure Class: | Threaded End- 2000LBS/ 3000LBS/ 6000LBS Socket-weld End- 3000LBS/ 6000LBS/ 9000LBS |

| Thread: | BSPT, NPT, BSPP |

| Test Certificates: | Third Party Inspection Report, 100% Radiography Test Report, Raw Materials Certificate, EN 10204/3.1B, etc. |

| Material Test Certificates (MTC): | As per EN 10204 3.1 and EN 10204 3.2, TC certifying NACE MR0103, NACE MR0175 |

| Manufacturers of: | 90º Elbows, 45º Elbows, Equal Tee, Reducing Tee, Lateral Tee, Cross, Reducers, Half Coupling, Full Coupling, End Cap, Union, Reducer Insert, Boss, Nipple, Adapters, Street Elbow, Reducing Coupling, Bushing, Hex Plug, Square Head Plug, Round Head Plug, Bull Plug, Branch Outlet, 90° Outlet Elbow. |

| Uses & Applications: | Petrochemicals and acids, Nuclear Power, Heavy oil refineries, Bitumen upgraders. |

| Product Name: | Carbon Steel Flanges |

| Specifications: | ASTM A105 / ASME SA105, ASTM A350 / ASME SA350, ASTM A694 / ASME SA694 |

| size: | 1/2″ (15 NB) to 48″ (1200NB) DN10~DN5000 |

| Dimensions: | ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom Drawings |

| Standard: | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges etc. |

| Pressure Class: | Class 150 LBS, 300 LBS, 400 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS | PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Coating: | Anti-rust Paint, Oil Black Paint, Yellow Transparent, Zinc Plated, Cold and Hot Dip Galvanized |

| common types: | Forged / Screwed / Threaded / Plate |

| Test Certificates: | Third Party Inspection Report, 100% Radiography Test Report, Raw Materials Certificate, EN 10204/3.1B, etc. |

| Flange Face Type: | Raised Face (RF), Flat Face (FF), Ring Type Joint (RTJ), Large Male-Female (LMF), Small Male-Female (SMF), Lap-Joint Face (LJF), Large Tongue & Groove (T&G). |

| Test Certificates (TC): | Raw Materials Certificate, EN 10204/3.1B, 100% Radiography Test Report, Third Party Inspection Report, etc |

| Material Test Certificates (MTC): | As per EN 10204 3.1 and EN 10204 3.2, TC certifying NACE MR0103, NACE MR0175 |

| Uses & Applications: | Petrochemicals and acids, Nuclear Power, Heavy oil refineries, Bitumen upgraders. |

GO TO FLANGES SECTION

GO TO BUTTWELD SECTION

GO TO FORGED FITTINGS SECTION

GO TO MATERIAL SECTION

Metalfed

Contact: +91 9137898594

Email: sales@metalfed.com

| www.metalfed.com

Metalfed | Mumbai| Maharashtra

Venezuela

Venezuela Myanmar

Myanmar Sri Lanka

Sri Lanka Belgium

Belgium Czechia

Czechia Greece

Greece Mexico

Mexico Tobago

Tobago Brazil

Brazil Chile

Chile France

France Colombia

Colombia South Africa

South Africa Jordan

Jordan Spain

Spain Hong Kong

Hong Kong Netherlands

Netherlands Poland

Poland Bangladesh

Bangladesh Indonesia

Indonesia Taiwan

Taiwan Nigeria

Nigeria Iraq

Iraq Ukraine

Ukraine Romania

Romania Cyprus

Cyprus Angola

Angola Norway

Norway USA

USA Saudi Arabia

Saudi Arabia Kuwait

Kuwait Thailand

Thailand South Korea

South Korea Singapore

Singapore Malaysia

Malaysia UAE

UAE Germany

Germany Italy

Italy Costa Rica

Costa Rica Kazakhstan

Kazakhstan Philippines

Philippines China

China UK

UK India

India Japan

Japan Russia

Russia Canada

Canada Iran

Iran Turkey

Turkey Morocco

Morocco Egypt

Egypt Vietnam

Vietnam Oman

Oman Australia

Australia Qatar

Qatar Portugal

Portugal