ASTM B462 UNS N08020 Flange, Carpenter 20 Pipe Flange, Alloy 20Cb3® Blind Flanges Manufacturer in India

Alloy 20 Flanges is widely used in springs, fasteners, washers, zippers, clips, clamps, computer parts, contacts, stampings for a variety of parts, pins and more. Alloy 20Cb3® Threaded Flanges is a commonly available austenitic steel with good corrosion resistance and high carbon content to allow cold workability in a wide range of tempers. It is a modification in which the chromium and nickel content is reduced to increase the work hardening range. Carpenter 20 Pipe Flange is suitable for all types of welding and shows good ductility in cold working. The chemistry of this steel enables it to be cold worked with the ideal combination of mechanical properties desired for specific applications.

We as a Metalfed Engineering is a well-known manufacturer, exporter, supplier and trader of Alloy 20 Lap Joint Flanges, which is a popular austenitic chromium-nickel steel known for its resistance to corrosion. It is not hardenable by heat treatment. WNR 2.4660 Weld Neck Flanges is an austenitic chromium-nickel steel that offers high strength and good ductility when cold worked. Strength and good corrosion resistance in slightly corrosive environments at room temperature. ASTM B46 UNS N08020 Threaded Reducing Flanges is non-magnetic when annealed but becomes magnetic after cold working. It has the highest tensile strength among forged austenitic stainless steels.

Reputed Exporter of Alloy 20 Weld Neck Flange, ASTM B462 Alloy 20 Socket Weld Flange, Alloy UNS N08020 Slip on Flange, ASME SB462 Alloy 20 Orifice Flange, ASME B16.5 Alloy 20 Threaded Flange, Incoloy Alloy 20 SORF Flange in all Dimensions and Sizes.

Alloy 20 Socket Weld Flanges is also used in automobile trims, kitchen appliances, hose clamps, hubcaps, etc. High strength and excellent corrosion resistance make this Alloy 20 Slip On Flanges suitable for a wide range of applications. Buy Alloy 20 Flanges at best price.

- Epoxy Coating

- Electro Polish

- Sand Blasting

- Intergranular Corrosion Test

- Tensile Test

- Hardness Test

- Good load bearing capacity

- Excellent versatility and weldability

- High tensile strength

Largest Stockists of WERKSTOFF NR. 2.4660 Lap Joint Flange, Alloy 20 Spectacle Blind Flange, Carpenter 20 Plate Flange, ASME SB462 Alloy 20 RTJ Flange, Alloy UNS N08020 Forged Flange, Alloy 20 Slip-on Flange at Best Price in India.

Alloy 20 Flanges Specifications

| Product Name: | Alloy 20 Flanges |

| Specifications: | ASTM B 462/ ASME SB 462 |

| size: | 1/2″ (15 NB) to 48″ (1200NB) DN10~DN5000 |

| Dimensions: | ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom Drawings |

| Standard: | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges etc. |

| Pressure Class: | Class 150 LBS, 300 LBS, 400 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS | PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Coating: | Anti-rust Paint, Oil Black Paint, Yellow Transparent, Zinc Plated, Cold and Hot Dip Galvanized |

| common types: | Forged / Screwed / Threaded / Plate |

| Test Certificates: | Third Party Inspection Report, 100% Radiography Test Report, Raw Materials Certificate, EN 10204/3.1B, etc. |

| Flange Face Type: | Raised Face (RF), Flat Face (FF), Ring Type Joint (RTJ), Large Male-Female (LMF), Small Male-Female (SMF), Lap-Joint Face (LJF), Large Tongue & Groove (T&G). |

| Test Certificates (TC): | Raw Materials Certificate, EN 10204/3.1B, 100% Radiography Test Report, Third Party Inspection Report, etc |

| Material Test Certificates (MTC): | As per EN 10204 3.1 and EN 10204 3.2, TC certifying NACE MR0103, NACE MR0175 |

| Uses & Applications: | Petrochemicals and acids, Nuclear Power, Heavy oil refineries, Bitumen upgraders. |

| Export Network: | Ireland, Oman, Dubai, Indonesia, Egypt, Singapore, Saudi & Arabia, Iran, Ukraine, Canada, USA, Brazil, Spain, Thailand, Korea, India, Peru, etc |

ASTM B462 UNS N08020 Flanges Equivalent Grades

| STANDARD | WERKSTOFF NR. | UNS | EN | AFNOR |

| Alloy 20 | 2.4660 | N08020 | NiCr20CuMo | Z2NCUD31-20AZ |

Alloy 20 Flanges Chemical Composition

| Grade | C | Mn | Si | S | Cu | Ni | Cr | Fe | Mo | P |

| Alloy 20 | 0.07 max | 2.00 max | 1.00 max | 0.035 max | 3.00 – 4.00 | 32.00 – 38.00 | 19.00 – 21.00 | 29.85 min* | 2.00 – 3.00 | 0.045 max |

Incoloy Alloy 20 Flanges Mechanical Properties

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Alloy 20 | 8.1 g/cm3 | 1443 °C (2430 °F) | Psi -80,000, MPa -551 | Psi – 35,000, MPa – 241 | 30 % |

Alloy 20 Flanges Size Range

| Below Mentioned Incoloy Alloy 20 Flanges Size: 1/8″ – 36″ | |

| ASTM B462 UNS N08020 Slip-On Flanges | ASTM B462 Alloy 20 Threaded Flanges |

| ASTM B462 Alloy 20 Lap Joint Flanges | ASTM B462 UNS N08020 Plate Flanges |

| ASTM B462 Alloy 20 Weld Neck Flanges | ASTM B462 Alloy 20 Socket Weld Flanges |

| ASTM B462 Alloy 20 Blind Flanges | ASTM B462 Alloy 20 Reducing Flanges |

| ASTM B462 UNS N08020 Ring Type Joint Flanges | ASTM B462 UNS N08020 Square Flanges |

| ASTM B462 UNS N08020 Orifice Flanges | ASTM B462 UNS N08020 Forged Flanges |

Alloy 20 Pipe Flanges Manufacturing Standards

| American Steel Flanges Standard | |

| Standard Name | Standard Code |

| Forged Flanges | ANSI ASME SB-462 |

| Lap joint flange, Welding neck flange, Slip on flange, Threaded flange, Blind flange, RTJ flange | ANSI ASME B16.5 |

| Blind flange, Welding neck flange | ASME – B 16.47 |

| Welding neck flange, Slip on flange | ASME – B 16.36 |

| German Steel Flanges Standard | |

| BLRF, Steel Blind Flanges | DIN 2527 |

| Flat Flange for Welding (Slip On) | DIN 2573 / 2576 |

| Loose Flanges and Rings for Welding (Slip On Flanges and Plain Collars) | DIN 2673 |

| Lapped / Loose (Lap Joint) Flanges Plain Collars | DIN 2641 / 2642 |

| Long Neck Welding Flanges | DIN 28115 |

| Alloy 20 PN10 Flanges, DIN PN 10 Flanges, PN16 Flange | DIN PN10, PN16 |

| Alloy 20 PN20 Flanges, DIN PN 25 Flanges | DIN PN20, PN25 |

| Alloy 20 PN40 Flanges, DIN PN 50 Flanges | DIN PN40, PN50 |

| Japanese Steel Flanges Standard | |

| Slip-on Hub (SOH), Slip-on plate flange (SOP), Welding neck flange (WN), Socket Welding flange (SW), Lapjoint (LJ), Threaded flange (TR)/ Itegral flange (IT) Blank flange (BL) | JIS B2220 |

| Socket Welding flange (SW), Slip-on plate flange (SOP), Welding neck flange (WN), Slip-on Hub (SOH), Lapjoint (LJ), Threaded flange (TR)/ Itegral flange (IT) Blank flange (BL) | JIS B2291 |

| Alloy 20 5K SORF Flanges, 10K SOFF Flanges | JIS 5K, 10K |

| Alloy 20 16K Blind Flanges, 20K BLRF Flanges | JIS 16K, 20K |

| Alloy 20 30K Slip on Flanges, 40K Blind Flanges | JIS 30K, 40K |

| Italian Flanges Standard | |

| Plan flanges (2276, 2277, 2278, 6083, 6084) Welding neck (2280, 2281, 2282, 2283, 2284, 2285, 2286) Lapped flanges (6088, 6089, 6090, 2999, 2300) Blind flanges (6091, 6092, 6093, 6094, 6095, 6096, 6097) threaded flanges (2253, 2254) | UNI Flanges |

| British Standard Pipe Flanges Standard | |

| Alloy 20 BS 10 Table D Flanges, Table D Pipe Flange | BS 10 Table D |

| Alloy 20 BS 10 Table E Flanges, Table E Pipe Flange | BS 10 Table E |

| Alloy 20 BS 10 Table E Flanges, Table E Flanges | BS 10 Table F |

| Alloy 20 BS 10 Table E Flanges, Table E Pipe Flanges | BS 10 Table H |

Incoloy Alloy 20 Flanges Dimensions

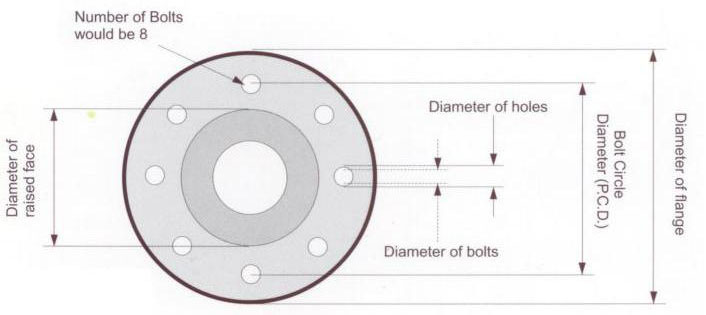

Alloy 20 Flanges are commonly used to connect valves into pipework making it easier for removal and maintenance. There are many common flange standards and flanges within the same standard can etiher be flat or raised face. Below is a reference table for critical flange dimensions.

| Standard | Class | Diameter | Bolt Circle Diameter | Number of Bolts | Bolt Size | Diameter of Bolt Hole |

|---|---|---|---|---|---|---|

| 15mm (1/2″) | ||||||

| ANSI B16.5 | ANSI 150 | 89 | 60 | 4 | 13 | 16 |

| ANSI 300 | 95 | 67 | 4 | 13 | 16 | |

| ANSI 600 | 95 | 67 | 4 | 13 | 16 | |

| ANSI 900 | 121 | 83 | 4 | 19 | 22 | |

| ANSI 1500 | 121 | 83 | 4 | 19 | 22 | |

| 20mm (3/4″) | ||||||

| ANSI B16.5 | ANSI 150 | 98 | 70 | 4 | 13 | 16 |

| ANSI 300 | 117 | 83 | 4 | 16 | 19 | |

| ANSI 600 | 117 | 83 | 4 | 16 | 19 | |

| ANSI 900 | 130 | 89 | 4 | 19 | 22 | |

| ANSI 1500 | 130 | 89 | 4 | 19 | 22 | |

| 25mm (1″) | ||||||

| ANSI B16.5 | ANSI 150 | 110 | 79 | 4 | 13 | 16 |

| ANSI 300 | 125 | 89 | 4 | 16 | 19 | |

| ANSI 600 | 125 | 89 | 4 | 16 | 19 | |

| ANSI 900 | 102 | 4 | 22 | 25 | ||

| ANSI 1500 | 102 | 4 | 22 | 25 | ||

| 32mm (1 1/4″) | ||||||

| ANSI B16.5 | ANSI 150 | 117 | 89 | 4 | 13 | 16 |

| ANSI 300 | 133 | 98 | 4 | 16 | 19 | |

| ANSI 600 | 133 | 98 | 4 | 16 | 19 | |

| ANSI 900 | 159 | 111 | 4 | 22 | 25 | |

| ANSI 1500 | 159 | 111 | 4 | 22 | 25 | |

| 40mm (1 1/2″) | ||||||

| ANSI B16.5 | ANSI 150 | 127 | 98 | 4 | 13 | 16 |

| ANSI 300 | 156 | 114 | 4 | 19 | 22 | |

| ANSI 600 | 156 | 114 | 4 | 19 | 22 | |

| ANSI 900 | 178 | 124 | 4 | 25 | 29 | |

| ANSI 1500 | 178 | 124 | 4 | 25 | 29 | |

| 50mm (2″) | ||||||

| ANSI B16.5 | ANSI 150 | 152 | 121 | 4 | 16 | 19 |

| ANSI 300 | 165 | 127 | 8 | 16 | 19 | |

| ANSI 600 | 165 | 127 | 8 | 16 | 19 | |

| ANSI 900 | 216 | 165 | 8 | 22 | 25 | |

| ANSI 1500 | 216 | 165 | 8 | 22 | 25 | |

| 65mm (2 1/2″) | ||||||

| ANSI B16.5 | ANSI 150 | 178 | 140 | 4 | 16 | 19 |

| ANSI 300 | 191 | 149 | 8 | 19 | 22 | |

| ANSI 600 | 191 | 149 | 8 | 19 | 22 | |

| ANSI 900 | 244 | 191 | 8 | 22 | 25 | |

| ANSI 1500 | 244 | 191 | 8 | 25 | 29 | |

| 80mm (3″) | ||||||

| ANSI B16.5 | ANSI 150 | 191 | 152 | 4 | 16 | 19 |

| ANSI 300 | 210 | 168 | 8 | 19 | 22 | |

| ANSI 600 | 210 | 168 | 8 | 19 | 22 | |

| ANSI 900 | 241 | 192 | 8 | 22 | 25 | |

| ANSI 1500 | 267 | 203 | 8 | 29 | 32 | |

| 100mm (4″) | ||||||

| ANSI B16.5 | ANSI 150 | 229 | 191 | 8 | 16 | 19 |

| ANSI 300 | 254 | 200 | 8 | 19 | 22 | |

| ANSI 600 | 273 | 216 | 8 | 22 | 25 | |

| ANSI 900 | 292 | 235 | 8 | 29 | 32 | |

| ANSI 1500 | 311 | 241 | 8 | 32 | 35 | |

| 125mm (5″) | ||||||

| ANSI B16.5 | ANSI 150 | 254 | 216 | 8 | 19 | 22 |

| ANSI 300 | 279 | 235 | 8 | 19 | 22 | |

| ANSI 600 | 330 | 267 | 8 | 25 | 29 | |

| ANSI 900 | 349 | 279 | 8 | 32 | 35 | |

| ANSI 1500 | 375 | 292 | 8 | 38 | 41 | |

| 150mm (6″) | ||||||

| ANSI B16.5 | ANSI 150 | 279 | 241 | 8 | 19 | 22 |

| ANSI 300 | 318 | 270 | 12 | 19 | 22 | |

| ANSI 600 | 356 | 292 | 12 | 25 | 29 | |

| ANSI 900 | 381 | 318 | 12 | 29 | 32 | |

| ANSI 1500 | 394 | 318 | 12 | 35 | 38 | |

| 200mm (8″) | ||||||

| ANSI B16.5 | ANSI 150 | 343 | 298 | 8 | 19 | 22 |

| ANSI 300 | 381 | 330 | 12 | 19 | 22 | |

| ANSI 600 | 419 | 349 | 12 | 29 | 32 | |

| ANSI 900 | 470 | 394 | 12 | 35 | 38 | |

| ANSI 1500 | 483 | 394 | 12 | 41 | 44 | |

| 250mm (10″) | ||||||

| ANSI B16.5 | ANSI 150 | 406 | 362 | 12 | 22 | 25 |

| ANSI 300 | 445 | 387 | 16 | 25 | 29 | |

| ANSI 600 | 508 | 432 | 16 | 32 | 35 | |

| ANSI 900 | 546 | 470 | 16 | 35 | 38 | |

| ANSI 1500 | 584 | 483 | 12 | 41 | 51 | |

| 300mm (12″) | ||||||

| ANSI B16.5 | ANSI 150 | 483 | 432 | 12 | 22 | 25 |

| ANSI 300 | 521 | 451 | 16 | 29 | 32 | |

| ANSI 600 | 559 | 489 | 20 | 32 | 35 | |

| ANSI 900 | 610 | 533 | 20 | 35 | 38 | |

| ANSI 1500 | 673 | 571 | 16 | 51 | 54 | |

| 350mm (14″) | ||||||

| ANSI B16.5 | ANSI 150 | 533 | 476 | 12 | 25 | 29 |

| ANSI 300 | 584 | 514 | 20 | 29 | 32 | |

| ANSI 600 | 603 | 527 | 20 | 38 | 41 | |

| ANSI 900 | 641 | 559 | 20 | 38 | 41 | |

| ANSI 1500 | 749 | 635 | 16 | 57 | 60 | |

| 400mm (16″) | ||||||

| ANSI B16.5 | ANSI 150 | 597 | 540 | 16 | 25 | 29 |

| ANSI 300 | 648 | 572 | 20 | 32 | 35 | |

| ANSI 600 | 686 | 603 | 20 | 38 | 41 | |

| ANSI 900 | 705 | 616 | 20 | 41 | 44 | |

| ANSI 1500 | 826 | 705 | 16 | 64 | 67 | |

| 450mm (18″) | ||||||

| ANSI B16.5 | ANSI 150 Flange | 635 | 578 | 16 | 29 | 32 |

| ANSI 300 Flange | 711 | 629 | 24 | 32 | 35 | |

| ANSI 600 Flange | 743 | 654 | 20 | 41 | 44 | |

| ANSI 900 Flange | 787 | 686 | 20 | 48 | 51 | |

| ANSI 1500 Flange | 914 | 775 | 16 | 70 | 73 | |

| 500mm (20″) | ||||||

| ANSI B16.5 | ANSI 150 Flange | 699 | 635 | 20 | 29 | 32 |

| ANSI 300 Flange | 775 | 686 | 24 | 32 | 35 | |

| ANSI 600 Flange | 813 | 724 | 24 | 41 | 44 | |

| ANSI 900 Flange | 857 | 749 | 20 | 51 | 54 | |

| ANSI 1500 Flange | 984 | 832 | 16 | 76 | 79 | |

| 600mm (24″) | ||||||

| ANSI B16.5 | ANSI 150 Flanges | 813 | 749 | 20 | 32 | 35 |

| ANSI 300 Flanges | 914 | 813 | 24 | 38 | 41 | |

| ANSI 600 Flanges | 940 | 838 | 24 | 48 | 51 | |

| ANSI 900 Flanges | 1041 | 902 | 20 | 64 | 67 | |

| ANSI 1500 Flanges | 1168 | 991 | 16 | 89 | 92 | |

Weight Chart of Incoloy Alloy 20 Flanges

|

Pipe Normal Diam.

|

O.D. Flange

|

Thk. Of Flange Min

|

Diam.

of Hub |

Diameter of Raised Face

|

Length Hub.Y

|

Thread Length

|

Diam.

of Bolt Circle |

Diam.

of Bolt Holes |

Number

of Bolts |

Diam. of

Bolts (inch) |

KG

|

LB

|

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

inch

|

dn

|

O

|

C

|

X

|

G

|

Y

|

T

|

BC

|

BH

|

BN

|

BD

|

||

|

1/2"

|

15

|

89.00

|

11.20

|

30.20

|

35.10

|

15.70

|

15.70

|

60.50

|

15.80

|

4

|

1/2"

|

0.4

|

0.9

|

|

3/4"

|

20

|

98.50

|

12.70

|

38.10

|

42.90

|

15.70

|

15.70

|

69.90

|

15.80

|

4

|

1/2"

|

0.7

|

1.5

|

|

1"

|

25

|

108.00

|

14.20

|

49.30

|

50.80

|

17.50

|

17.50

|

79.30

|

15.80

|

4

|

1/2"

|

0.8

|

1.8

|

|

1-1/4"

|

32

|

117.50

|

15.70

|

58.70

|

63.50

|

20.60

|

20.60

|

88.90

|

15.80

|

4

|

1/2"

|

1.2

|

2.6

|

|

1-1/2"

|

40

|

127.00

|

17.50

|

65.00

|

73.20

|

22.40

|

22.40

|

98.60

|

15.80

|

4

|

1/2"

|

1.5

|

3.3

|

|

2"

|

50

|

152.50

|

19.10

|

77.70

|

91.90

|

25.40

|

25.40

|

120.70

|

19.10

|

4

|

5/8"

|

2.3

|

5.1

|

|

2-1/2"

|

65

|

178.00

|

22.40

|

90.40

|

104.60

|

28.40

|

28.40

|

139.70

|

19.10

|

4

|

5/8"

|

3.7

|

8.1

|

|

3"

|

80

|

190.50

|

23.90

|

108.00

|

127.00

|

30.20

|

30.20

|

152.40

|

19.10

|

4

|

5/8"

|

4.1

|

9

|

|

3-1/2"

|

90

|

216.00

|

23.90

|

122.20

|

139.70

|

31.80

|

31.80

|

177.80

|

19.10

|

8

|

5/8"

|

5.1

|

11.2

|

|

4"

|

100

|

228.50

|

23.90

|

134.90

|

157.20

|

33.30

|

33.30

|

190.50

|

19.10

|

8

|

5/8"

|

5.9

|

13

|

|

5"

|

125

|

254.00

|

23.90

|

163.60

|

185.70

|

36.60

|

36.60

|

215.90

|

22.40

|

8

|

3/4"

|

7

|

15.4

|

|

6"

|

150

|

279.50

|

25.40

|

192.00

|

215.90

|

39.60

|

39.60

|

241.30

|

22.40

|

8

|

3/4"

|

8.4

|

18.5

|

|

8"

|

200

|

343.00

|

28.40

|

246.10

|

269.70

|

44.50

|

44.50

|

298.50

|

22.40

|

8

|

3/4"

|

13

|

28.6

|

|

10"

|

250

|

406.50

|

30.20

|

304.80

|

323.90

|

49.30

|

49.30

|

362.00

|

25.40

|

12

|

7/8"

|

18

|

39.5

|

|

12"

|

300

|

482.50

|

31.80

|

365.30

|

381.00

|

55.60

|

55.60

|

431.80

|

25.40

|

12

|

7/8"

|

29

|

64

|

|

14"

|

350

|

533.50

|

35.10

|

400.10

|

412.80

|

57.20

|

57.20

|

476.30

|

28.50

|

12

|

1"

|

39

|

86

|

|

16"

|

400

|

597.00

|

36.60

|

457.20

|

469.90

|

63.50

|

63.50

|

539.80

|

28.50

|

16

|

1"

|

47

|

103

|

|

18"

|

450

|

635.00

|

39.60

|

505.00

|

533.40

|

68.30

|

68.30

|

577.90

|

31.80

|

16

|

1 1/8"

|

57

|

126

|

|

20"

|

500

|

698.50

|

42.90

|

558.80

|

584.20

|

73.20

|

73.20

|

635.00

|

31.80

|

20

|

1 1/8"

|

76

|

167

|

|

24"

|

600

|

813.00

|

47.80

|

663.40

|

692.20

|

82.60

|

82.60

|

749.30

|

35.10

|

20

|

1 1/4"

|

97

|

214

|

Schedule Class of ASTM B462 UNS N08020 Flanges

| Pipe Size – Pipe Flanges | Flange Schedule/Class | Flange Material | Flange Connection Type | Max. Pressure |

|---|---|---|---|---|

| 1/2" | ASME B16.5 Class 150 | Alloy 20 Flanges | FNPT | 150 psi |

| 1/2" | ASME B16.5 Class 150 | Alloy 20 Flanges | Socket Weld | 275 psi |

| 1/2" | ASME B16.5 Class 150 | Alloy 20 Flanges | Welded | 150 psi |

| 3/4" | ASME B16.5 Class 150 | Alloy 20 Flanges | FNPT | 150 psi |

| 3/4" | ASME B16.5 Class 150 | Alloy 20 Flanges | Socket Weld | 275 psi |

| 1-1/4" | ASME B16.5 Class 150 | Alloy 20 Flanges | Socket Weld | 275 psi |

| 1-1/2" | ASME B16.5 Class 150 | Alloy 20 Flanges | Socket Weld | 275 psi |

| 2" | ASME B16.5 Class 150 | Alloy 20 Flanges | FNPT | 150 psi |

| 2" | ASME B16.5 Class 150 | Alloy 20 Flanges | Socket Weld | 275 psi |

| 2-1/2" | ASME B16.5 Class 150 | Alloy 20 Flanges | Socket Weld | 275 psi |

| 3" | ASME B16.5 Class 150 | Alloy 20 Flanges | Socket Weld | 275 psi |

| 4" | ASME B16.5 Class 150 | Alloy 20 Flanges | FNPT | 150 psi |

| 4" | ASME B16.5 Class 150 | Alloy 20 Flanges | Socket Weld | 275 psi |

| 1/2" | ASME B16.5 Class 300 | Alloy 20 Flanges | Slip On | 720 psi |

| 1/2" | ASME B16.5 Class 300 | Alloy 20 Flanges | Slip On | 720 psi |

| 1" | ASME B16.5 Class 300 | Alloy 20 Flanges | Slip On | 720 psi |

| 1" | ASME B16.5 Class 300 | Alloy 20 Flanges | Slip On | 720 psi |

| 1-1/4" | ASME B16.5 Class 300 | Alloy 20 Flanges | FNPT | 720 psi |

| 1-1/4" | ASME B16.5 Class 300 | Alloy 20 Flanges | Slip On | 720 psi |

| 1-1/2" | ASME B16.5 Class 300 | Alloy 20 Flanges | Slip On | 720 psi |

| 1-1/2" | ASME B16.5 Class 300 | Alloy 20 Flanges | Slip On | 720 psi |

| 2" | ASME B16.5 Class 300 | Alloy 20 Flanges | Slip On | 720 psi |

| 2" | ASME B16.5 Class 300 | Alloy 20 Flanges | Slip On | 720 psi |

| 2-1/2" | ASME B16.5 Class 300 | Alloy 20 Flanges | Slip On | 720 psi |

| 2-1/2" | ASME B16.5 Class 300 | Alloy 20 Flanges | Slip On | 720 psi |

| 3" | ASME B16.5 Class 300 | Alloy 20 Flanges | Slip On | 720 psi |

| 3" | ASME B16.5 Class 300 | Alloy 20 Flanges | Slip On | 720 psi |

| 4" | ASME B16.5 Class 300 | Alloy 20 Flanges | Slip On | 720 psi |

| 4" | ASME B16.5 Class 300 | Alloy 20 Flanges | Slip On | 720 psi |

Alloy 20 Pipe Flanges Pressure Rating

| ANSI/ASME B16.34 | PRESSURE RATING CHART | ||||||

| Temperature °F | 150# | 300# | 400# | 600# | 900# | 1500# | 2500# |

| -20 to 100 | 275 | 720 | 960 | 1440 | 2160 | 3600 | 6000 |

| 200 | 230 | 600 | 800 | 1200 | 1800 | 3000 | 5000 |

| 300 | 205 | 540 | 720 | 1080 | 1620 | 2700 | 4500 |

| 400 | 190 | 495 | 660 | 995 | 1490 | 2485 | 4140 |

| 500 | 170 | 465 | 620 | 930 | 1395 | 2330 | 3880 |

| 600 | 140 | 435 | 580 | 875 | 1310 | 2185 | 3640 |

| 650 | 125 | 430 | 575 | 860 | 1290 | 2150 | 3580 |

| 700 | 110 | 425 | 565 | 850 | 1275 | 2125 | 3540 |

| 750 | 95 | 415 | 555 | 830 | 1245 | 2075 | 3460 |

| 800 | 80 | 405 | 540 | 805 | 1210 | 2015 | 3360 |

| 850 | 65 | 395 | 530 | 790 | 1190 | 1980 | 3300 |

| 900 | 50 | 390 | 520 | 780 | 1165 | 1945 | 3240 |

| 950 | 35 | 380 | 510 | 765 | 1145 | 1910 | 3180 |

| 1000 | 20 | 320 | 430 | 640 | 965 | 1605 | 2675 |

| 1050 | 20 | 310 | 410 | 615 | 925 | 1545 | 2570 |

| 1100 | 20 | 255 | 345 | 515 | 770 | 1285 | 2145 |

| 1150 | 20 | 200 | 265 | 400 | 595 | 995 | 1655 |

| 1200 | 20 | 155 | 205 | 310 | 465 | 770 | 1285 |

| 1250 | 20 | 115 | 150 | 225 | 340 | 565 | 945 |

| 1300 | 20 | 85 | 115 | 170 | 255 | 430 | 715 |

| 1350 | 20 | 60 | 80 | 125 | 185 | 310 | 515 |

| 1400 | 20 | 50 | 65 | 95 | 145 | 240 | 400 |

| 1450 | 15 | 35 | 45 | 70 | 105 | 170 | 285 |

| 1500 | 10 | 25 | 35 | 55 | 80 | 135 | 230 |

Alloy 20 Flanges Types and Prices

Slip-on Flanges

Alloy 20 Slip-on Flanges

Price: $10-$60 / Kilogram

Weld Neck Flanges

Alloy 20 Weld Neck Flanges

Price: US$1.98

Blind Flanges

Alloy 20 Blind Flanges

Price: US$10.23

Socket Weld Flanges

Alloy 20 Socket Weld Flanges

Price: US$10-30

Orifice Flanges

Alloy 20 Orifice Flanges (Weld Neck /Slip On/ Threaded Flanges)

Price: US$20-50

Threaded Flanges

Alloy 20 Threaded Flanges

Price: US$5.98

Lap Joint Flanges

Alloy 20 Lap Joint Flanges

Price: US$0.30

Spectacle Blind Flanges

Alloy 20 Spectacle Blind Flanges

Price: US$1.98

Ring Type Joint Flanges

Alloy 20 Ring Type Joint Flanges

Price: US$20

Forged Flanges

Alloy 20 Forged Flanges

Price: US$10-20

Flat Face Flange

Alloy 20 Flat Face Flange

Price: US$2.00

Tongue and Groove Flanges

Alloy 20 (T & G) Flanges

Price: US$30

Plate Flanges

Alloy 20 Plate Flanges

Price: US$10-50

API Type 6BX Flanges

Alloy 20 API Type 6BX (Weld Neck / Threaded) Flanges

Price: US$20-30

BS 10 Flanges

Alloy 20 BS 10 Flanges

Price: US$10-40

API Type 6B Flanges

Alloy 20 API Type 6B (Weld Neck/ Threaded) Flanges

Price: US$10-40

Paddle Blank and Spacer

Alloy 20 Paddle Blank and Spacer (RTJ Male Paddle Blank and Spacer)

Price: US$2.00

Compact Flanges

Alloy 20 Compact Flange (Swivel / Blind)

Price: US$1.98

Series A / B Weldneck Flange

Alloy 20 Series A / B Weldneck Flange

Price: US$1.98

Series A/ B Blind Flange

Alloy 20 Series A / B Blind Flange

Price: US$1.10

Threaded Reducing Flange

Alloy 20 Threaded Reducing Flange

Price: US$0.20

Figure 8 Flange (RTJ Male)

Alloy 20 Figure 8 Flange (RTJ Male)

Price: US$3.00

Male and Female Flange

Alloy 20 Male and Female Flange

Price: US$2.00

Flangeolet

Alloy 20 Flangeolet

Price: US$10-50

Note: Prices are based on product, material grade, and quantity. Contact us anytime to get full quotation.

ASTM B462 Alloy 20 Flanges – Applications & Industries

We are one of the oldest Manufacturers, Exporters, and Suppliers of high quality Alloy 20 Slip On Flanges. We supply ANSI B16.5 Carpenter 20 Weld Neck Flanges to customers in various industries including chemical, pharmaceutical, petrochemical, power, engineering and various other industrial applications. Test Certificate as per EN 10204 / 3.1B, Raw Materials Certificate, Third Party Inspection Report and 100% Radiography Test Report.

Ready Stock of ASTM B462 UNS N08020 Flanges Export to

Africa Algeria, Angola, Benin, Botswana, Burkina Faso, Burundi, Cabo Verde, Cameroon, Central African Republic (CAR), Chad, Comoros, The Democratic Republic of the Congo, Republic of the Congo, Cote d’Ivoire, Djibouti, Egypt, Equatorial Guinea, Eritrea, Ethiopia, Gabon, Gambia, Ghana, Guinea, Guinea-Bissau, Kenya, Lesotho, Liberia, Libya, Madagascar, Malawi, Mali, Mauritania, Mauritius, Morocco, Mozambique, Namibia, Niger, Nigeria, Rwanda, Sao Tome and Principe, Senegal, Seychelles, Sierra Leone, Somalia, South Africa, South Sudan, Sudan, Swaziland, Tanzania, Togo, Tunisia, Uganda, Zambia, Zimbabwe

Europe,Albania, Finland, France, Ireland, Italy, Andorra, Armenia, Austria, Bosnia and Herzegovina, Bulgaria, Croatia, Cyprus, Czech Republic, Georgia, Germany, Denmark, Estonia, Kazakhstan, Kosovo, Greece, Hungary, Iceland, Latvia, Liechtenstein, Azerbaijan, Belarus, Belgium, Lithuania, Luxembourg, Macedonia, Malta, Moldova, Monaco, Montenegro, Netherlands, Norway, Poland, Portugal, Romania, Russia, San Marino, Serbia, Slovakia, Slovenia, Spain, Sweden, Turkey, Ukraine, United Kingdom, Vatican City

AmericaAntigua and Barbuda, Bahamas, Barbados, Belize, Canada, Costa Rica, Cuba, Dominica, Dominican Republic, El Salvador, Grenada, Guatemala, Haiti, Honduras, Jamaica, Mexico, Nicaragua, Panama, Saint Kitts and Nevis, Saint Lucia, Saint Vincent and the Grenadines, Trinidad and Tobago, United States of America, Argentina, Bolivia, Brazil, Chile, Colombia, Ecuador, Guyana, Paraguay, Peru, Suriname, Uruguay, Venezuela

Asia/OceaniaAfghanistan, Armenia, Azerbaijan, Bahrain, Bangladesh, Bhutan, Brunei, Cambodia, China, Cyprus, Georgia, India, Indonesia, Iran, Iraq, Israel, Japan, Jordan, Laos, Lebanon, Malaysia, Maldives, Mongolia, Myanmar (Burma), Oman, Pakistan, Palestine, Philippines, Qatar, Nepal, North Korea, Russia, Saudi Arabia, Singapore, South Korea, Sri Lanka, Syria, Taiwan, Tajikistan, Thailand, Timor-Leste, Turkey, Turkmenistan, United Arab Emirates (UAE), Uzbekistan, Vietnam, Yemen, Australia, Fiji, Kiribati, Marshall Islands, Micronesia, Nauru, New Zealand, Palau, Papua New Guinea, Samoa, Solomon Islands, Tonga, Tuvalu, Vanuatu

Please send us the complete details of Alloy 20 Flanges requirement. We offer Carpenter 20 SORF Flanges, and ASTM B462 UNS N08020 Blind Flanges which are accurately designed to provide satisfaction to our customers. We have ready stock of Alloy 20 Socket Weld Flange, Alloy 20Cb3® Orifice Flange, Alloy 20 B462 Lap Joint Flange at our valuable customers end. Buy Alloy 20 Flangeat a cheap price from us.

sales@metalfed.com | +91 9137898594 | Quotation Form | Reach Us

Venezuela

Venezuela Myanmar

Myanmar Sri Lanka

Sri Lanka Belgium

Belgium Czechia

Czechia Greece

Greece Mexico

Mexico Tobago

Tobago Brazil

Brazil Chile

Chile France

France Colombia

Colombia South Africa

South Africa Jordan

Jordan Spain

Spain Hong Kong

Hong Kong Netherlands

Netherlands Poland

Poland Bangladesh

Bangladesh Indonesia

Indonesia Taiwan

Taiwan Nigeria

Nigeria Iraq

Iraq Ukraine

Ukraine Romania

Romania Cyprus

Cyprus Angola

Angola Norway

Norway USA

USA Saudi Arabia

Saudi Arabia Kuwait

Kuwait Thailand

Thailand South Korea

South Korea Singapore

Singapore Malaysia

Malaysia UAE

UAE Germany

Germany Italy

Italy Costa Rica

Costa Rica Kazakhstan

Kazakhstan Philippines

Philippines China

China UK

UK India

India Japan

Japan Russia

Russia Canada

Canada Iran

Iran Turkey

Turkey Morocco

Morocco Egypt

Egypt Vietnam

Vietnam Oman

Oman Australia

Australia Qatar

Qatar Portugal

Portugal