EN 1092-1 Flange Suppliers in India

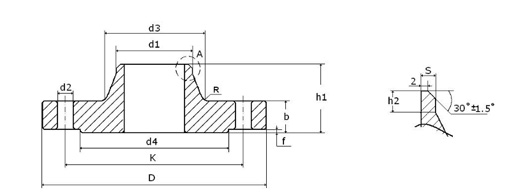

EN 1092-1 Type 01 Flanges Dimensions, EN 1092-1 Type 02 Flanges

Metalfed Engineering is a leading supplier, exporter, and manufacturers of Industrial Pipe Flanges. A flange is a method of connecting pipes, valves, pumps and other equipment to form a piping system. It also provides easy access for cleaning, inspection or modification. Flanges are usually welded or screwed. Flanged joints are made by bolting together two flanges with a gasket between them to provide a seal. Using flanges adds flexibility when maintaining piping systems by allowing for easier disassembly and improved access to system components. A typical flanged connection is comprised of three parts i.e. Pipe Flanges, Gasket, and Bolting. In most cases, there are specific gasket and bolting materials made from the same, or approved materials as the piping components you wish to connect. Stainless Steel flanges are some of the most common. However, flanges are available in a wide range of materials so matching them with your needs is essential. Other common flange materials include Monel, Inconel, Chrome Moly, and many others depending on the application.

A Specialized Manufacturer of EN 1092-1 Type 05 Flanges, EN 1092-1 Type 11 Flanges, EN 1092-1 Type 13 Flanges, EN 1092-1 Type 02 Flanges, EN 1092-1 Type 01 Flanges in all Dimensions & Sizes.

Common face types include: Flat Face (FF)- As the name suggests, flat face flanges feature a flat, even surface combined with a full face gasket that contacts most of the flange surface. Raised Face (RF)- These flanges feature a small raised section around the bore with an inside bore circle gasket. Ring Joint Face (RTJ)- Used in high-pressure and high-temperature processes, this face type features a groove in which a metal gasket sits to maintain the seal. Tongue and Groove (T&G)- These flanges feature matching grooves and raised sections. This aids in installation as the design helps the flanges to self-align and provides a reservoir for gasket adhesive. Male & Female (M&F)- Similar to tongue and groove flanges, these flanges use a matching pair of grooves and raised sections to secure the gasket. However, unlike tongue and groove flanges, these retain the gasket on the female face, providing more accurate placement and increased gasket material options.

Largest Stockists of EN 1092-1 PN6 Flanges, EN 1092-1 PN10 Flanges, EN 1092-1 PN16 Flanges, EN 1092-1 PN25 Flanges, EN 1092-1 PN40 Flanges, EN 1092-1 Plate Flanges, EN 1092-1 Loose Flanges, EN 1092-1 Blind Flanges, EN 1092-1 WNRF Flanges, EN 1092-1 Threaded Flangeat Best Prices.

EN 1092-1 Flange Specifications

| Standard Name: | EN 1092-1 Flange |

| Size Chart: | 1/2″ (15 NB) to 48″ (1200NB) DN10~DN5000 |

| Dimensions: | EN 1092-1 Type 02 Flanges, EN 1092-1 Type 01 Flanges, EN 1092-1 Type 05 Flanges, EN 1092-1 Type 11 Flanges, EN 1092-1 Type 13 Flanges |

| Pressure Rating: | Class 150 LBS, 300 LBS, 400 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

| Pressure Calculation in DIN: | PN6 PN10 PN16 PN25 PN40 PN64 / 6Bar 10Bar 16Bar 25Bar 40Bar |

| Coating/Surface Treatment: | Anti-rust Paint, Oil Black Paint, Yellow Transparent, Zinc Plated, Cold and Hot Dip Galvanized |

| Connection Type/Flange Face Type: | RF-Raised Face, RTJ-Ring Type Joint, FF-Flat Face, LMF-Large Male-Female, LJF-Lap-Joint Face, SMF-Small Male-Female, Small Tongue, Large Tongue & Groove, Groove |

| Custom Flange/Special Design: | As per your drawing |

| Flange Test: | Direct-reading Spectrograph, X-ray detector, Hydrostatic testing machine, UI trasonic flaw detector, Magnetic particle detector |

| Flanges Equipment: | Press machine, Pushing Machine, Bending machine, electric bevelling machine, Sand-blasting machine, etc |

| Test Certificates: | Third Party Inspection Report, 100% Radiography Test Report, Raw Materials Certificate, EN 10204/3.1B, etc. |

| Material Test Certificates (MTC): | As per EN 10204 3.1 and EN 10204 3.2, TC certifying NACE MR0103, NACE MR0175 |

| Uses & Applications: | Petrochemicals and acids, Nuclear Power, Heavy oil refineries, Bitumen upgraders, Offshore, Piping Projects etc. |

| Export Network: | Ireland, Oman, Dubai, Indonesia, Egypt, Singapore, Saudi & Arabia, Iran, Ukraine, Canada, USA, Brazil, Spain, Thailand, Korea, India, Peru, etc |

EN 1092-1 Flange Materials and Grades

| Duplex Steel EN 1092-1 Flange: | ASTM / ASME A/SA 182 F44, F45, F51, F53, F55, F60, F61 |

| Super Duplex EN 1092-1 Flange: | ASTM / ASME A/SA 182 F44, F45, F51, F53, F55, F60, F61 |

| Stainless Steel EN 1092-1 Flange: | ASTM A 182, A 240 F 304, 304L, 304H, 316, 316L, 316Ti, 310, 310S, 321, 321H, 317, 347, 347H, 904L |

| Nickel Alloys EN 1092-1 Flange: | ASTM SB564, SB160, SB472, SB162 – Nickel 200 (UNS No. N02200), Nickel 201 (UNS No. N02201), Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500), Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel 600 (UNS No. N06600), Inconel 625 (UNS No. N06625), Inconel 601 (UNS No. N06601), Hastelloy C 276 (UNS No. N10276), Alloy 20 (UNS No. N08020) |

| Alloys EN 1092-1 Flange: | Alloy 20, Alloy C, Alloy C276, Alloy B2 |

| Carbon Steel EN 1092-1 Flange: | STM / ASME A/SA 105 ASTM / ASME A 350, ASTM A 181 LF 2 / A516 Gr.70 A36, A694 F42, F46, F52 |

| Copper Alloys EN 1092-1 Flange: | ASTM SB 61, SB62, SB151, SB152 – UNS No. C 70600 (Cu-Ni 90/10), C 71500 (Cu-Ni 70/30), UNS No. C 10100, 10200, 10300, 10800, 12000, 12200 |

| Low Temperature Steel EN 1092-1 Flange: | ASTM A350 LF2, LF3, LF6 |

| High Yield EN 1092-1 Flange: | ASTM A694 F42, F52, F60, F65, F70 |

| Alloy Steel EN 1092-1 Flange: | ASTM / ASME A/SA 182 & A 387 F1, F5, F9, F11, F12, F22, F91 |

| Titanium EN 1092-1 Flange: | Gr1, Gr2, Gr3, Gr5, Gr7, Gr11 |

| Brass EN 1092-1 Flange: | 2604 / 3602 / H59 / H62 / etc. |

| Aluminium EN 1092-1 Flange: | 2017 / 5052 / 6063 / 6061 / 7075 etc. |

| Alloy 20 EN 1092-1 Flange: | ASME SB462 / ASTM B462, Carpenter® 20 Alloy, Alloy 20Cb-3 |

| Nimonic EN 1092-1 Flange: | Nimonic 80A, Nimonic 75, Nimonic 90 |

| 254 SMO EN 1092-1 Flange: | ASME SA182 / ASTM A182, SMO 254/6Mo, UNS S31254, DIN 1.4547 |

| Other EN 1092-1 Flange Material: | Tin bronze, Alumunum bronze, Lead bronze |

EN 1092-1 type 01 pn6 Flange Dimensions

| Rated Diameter | Pipe | Flange | Screws |

Weight/KG Flange |

|||||

| X | C | D | T | h | Thread | Bolt holes | KG | ||

| 15 | 21,3 | 22,0 | 55 | 80 | 12 | 11 | M10 | 4 | 0,401 |

| 20 | 26,9 | 27,5 | 65 | 90 | 14 | 11 | M10 | 4 | 0,590 |

| 25 | 33,7 | 34,5 | 75 | 100 | 14 | 11 | M10 | 4 | 0,716 |

| 32 | 42,4 | 43,5 | 90 | 120 | 16 | 14 | M12 | 4 | 1,153 |

| 40 | 48,3 | 49,5 | 100 | 130 | 16 | 14 | M12 | 4 | 1,344 |

| 50 | 60,3 | 61,5 | 110 | 140 | 16 | 14 | M12 | 4 | 1,478 |

| 65 | 76,1 | 77,5 | 130 | 160 | 16 | 14 | M12 | 4 | 1,850 |

| 80 | 88,9 | 90,5 | 150 | 190 | 18 | 18 | M16 | 4 | 2,944 |

| 100 | 114,3 | 116,0 | 170 | 210 | 18 | 18 | M16 | 4 | 3,247 |

| 125 | 139,7 | 141,5 | 200 | 240 | 20 | 18 | M16 | 8 | 4,301 |

| 150 | 168,3 | 170,5 | 225 | 265 | 20 | 18 | M16 | 8 | 4,741 |

| 200 | 219,1 | 221,5 | 280 | 320 | 22 | 18 | M16 | 8 | 6,862 |

| 250 | 273,0 | 276,5 | 335 | 375 | 24 | 18 | M16 | 12 | 8,893 |

| 300 | 323,9 | 327,5 | 395 | 440 | 24 | 22 | M20 | 12 | 11,880 |

| 350 | 355,6 | 359,5 | 445 | 490 | 26 | 22 | M20 | 12 | 16,788 |

| 400 | 406,4 | 411,0 | 495 | 540 | 28 | 22 | M20 | 16 | 19,781 |

| 450 | 457,0 | 462,0 | 550 | 595 | 30 | 22 | M20 | 16 | 24,495 |

| 500 | 508,0 | 513,5 | 600 | 645 | 30 | 22 | M20 | 20 | 26,307 |

| 600 | 610,0 | 616,5 | 705 | 755 | 32 | 26 | M24 | 20 | 34,702 |

| 700 | 711,0 | 714,2 | 810 | 860 | 40 | 26 | M24 | 24 | 52,441 |

| 800 | 813,0 | 815,8 | 920 | 975 | 44 | 30 | M27 | 24 | 71,262 |

| 900 | 914,0 | 917,4 | 1020 | 1075 | 48 | 30 | M27 | 24 | 86,269 |

| 1000 | 1016,0 | 1019,0 | 1120 | 1175 | 52 | 30 | M27 | 28 | 101,340 |

| 1200 | 1220,0 | 1224,0 | 1340 | 1405 | 60 | 33 | M30 | 32 | 162,638 |

| 1400 | 1420,0 | 1424,0 | 1560 | 1630 | 72 | 36 | M33 | 36 | 257,772 |

| 1600 | 1620,0 | 1624,0 | 1760 | 1830 | 80 | 36 | M33 | 40 | 324,382 |

| 1800 | 1820,0 | 1826,0 | 1970 | 2045 | 88 | 39 | M36 | 44 | 422,35 |

| 2000 | 2020,0 | 2026,0 | 2180 | 2265 | 96 | 42 | M39 | 48 | 555,18 |

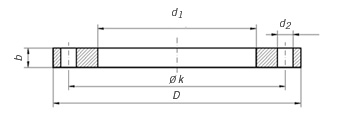

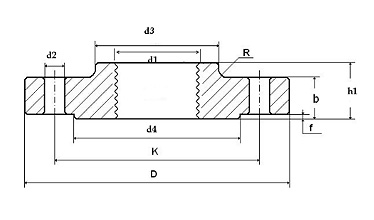

EN 1092-1 Loose PN10 Flanges Dimensions

| EN 1092-1 TYPE 02 PN10 LOOSE FLANGE | |||||||||

| Rated Diameter | Flange | Screws | Weight (7,85 Kg/dm3) |

||||||

| d1 | k | D | b | e | d2 | Thread | Bolt holes | KG | |

| 15 | 25 | 65 | 95 | 14 | 3 | 14 | M12 | 4 | 0,654 |

| 20 | 31 | 75 | 105 | 16 | 4 | 14 | M12 | 4 | 0,913 |

| 25 | 38 | 85 | 115 | 16 | 4 | 14 | M12 | 4 | 1,081 |

| 32 | 47 | 100 | 140 | 18 | 5 | 18 | M16 | 4 | 1,781 |

| 40 | 53 | 110 | 150 | 18 | 5 | 18 | M16 | 4 | 2,035 |

| 50 | 65 | 125 | 165 | 20 | 5 | 18 | M16 | 8 | 2,520 |

| 65 | 81 | 145 | 185 | 20 | 6 | 18 | M16 | 8 | 3,050 |

| 80 | 94 | 160 | 200 | 20 | 6 | 18 | M16 | 8 | 3,480 |

| 100 | 120 | 180 | 220 | 22 | 6 | 18 | M16 | 8 | 4,200 |

| 125 | 145 | 210 | 250 | 22 | 6 | 18 | M16 | 8 | 5,210 |

| 150 | 174 | 240 | 285 | 24 | 6 | 22 | M20 | 8 | 6,890 |

| 200 | 226 | 295 | 340 | 24 | 6 | 22 | M20 | 8 | 8.870 |

| 250 | 281 | 350 | 395 | 26 | 8 | 22 | M20 | 12 | 11,200 |

| 300 | 333 | 400 | 445 | 26 | 8 | 22 | M20 | 12 | 12,800 |

| 350 | 365 | 460 | 505 | 30 | 8 | 22 | M20 | 16 | 19,400 |

| 400 | 416 | 515 | 565 | 32 | 8 | 26 | M24 | 16 | 26,400 |

| 450 | 467 | 565 | 615 | 36 | 8 | 26 | M24 | 20 | 32,200 |

| 500 | 519 | 620 | 670 | 38 | 8 | 26 | M24 | 20 | 38,500 |

| 600 | 622 | 725 | 780 | 42 | 8 | 30 | M27 | 20 | 52,200 |

| 700 | 721 | 840 | 895 | 50 | 8 | 30 | M27 | 24 | 79,400 |

| 800 | 824 | 950 | 1015 | 56 | 8 | 33 | M30 | 24 | 112,000 |

| 900 | 926 | 1050 | 1115 | 62 | 8 | 33 | M30 | 28 | 135,000 |

| 1000 | 1028 | 1160 | 1230 | 70 | 8 | 36 | M33 | 28 | 180,000 |

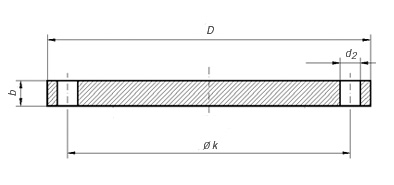

EN 1092 1 Blind pn6 Flange Dimensions

| EN 1092-1 TYPE 05 PN6 BLIND FLANGE | |||||||

| Diameter | Flange | Screws | Weight (7,85 Kg/dm3) |

||||

| k | D | b | d2 | Thread | Bolt holes | KG | |

| 15 | 55 | 80 | 12 | 11 | M10 | 4 | 0,438 |

| 20 | 65 | 90 | 14 | 11 | M10 | 4 | 0,657 |

| 25 | 75 | 100 | 14 | 11 | M10 | 4 | 0,821 |

| 32 | 90 | 120 | 14 | 14 | M12 | 4 | 1,180 |

| 40 | 100 | 130 | 14 | 14 | M12 | 4 | 1,390 |

| 50 | 110 | 140 | 14 | 14 | M12 | 4 | 1,620 |

| 65 | 130 | 160 | 14 | 14 | M12 | 4 | 2,140 |

| 80 | 150 | 190 | 16 | 18 | M16 | 4 | 3,430 |

| 100 | 170 | 210 | 16 | 18 | M16 | 4 | 4,220 |

| 125 | 200 | 240 | 18 | 18 | M16 | 8 | 6,100 |

| 150 | 225 | 265 | 18 | 18 | M16 | 8 | 7,510 |

| 200 | 280 | 320 | 20 | 18 | M16 | 8 | 12,300 |

| 250 | 335 | 375 | 22 | 18 | M16 | 12 | 18,500 |

| 300 | 395 | 440 | 22 | 22 | M20 | 12 | 25,500 |

| 350 | 445 | 490 | 22 | 22 | M20 | 12 | 31,800 |

| 400 | 495 | 540 | 22 | 22 | M20 | 16 | 38,500 |

| 450 | 550 | 595 | 24 | 22 | M20 | 16 | 51,200 |

| 500 | 600 | 645 | 24 | 22 | M20 | 20 | 60,100 |

| 600 | 705 | 755 | 30 | 26 | M24 | 20 | 103,000 |

| 700 | 810 | 860 | 40 | 26 | M24 | 24 | 178,000 |

| 800 | 920 | 975 | 44 | 30 | M27 | 24 | 252,000 |

| 900 | 1020 | 1075 | 48 | 30 | M27 | 24 | 336,000 |

| 1000 | 1120 | 1175 | 52 | 30 | M27 | 28 | 435,000 |

| 1200 | 1340 | 1405 | 60 | 33 | M30 | 32 | 717,000 |

| 1400 | 1560 | 1630 | 68 | 36 | M33 | 36 | 1.094,000 |

| 1600 | 1760 | 1830 | 76 | 36 | M33 | 40 | 1.545,000 |

| 1800 | 1970 | 2045 | 84 | 39 | M36 | 44 | 2.131,000 |

| 2000 | 2180 | 2265 | 92 | 42 | M39 | 48 | 2.862,000 |

EN 1092-1 Type 11 pn6 Flange Dimensions

| EN 1092-1 TYPE 05 PN6 BLIND FLANGE | |||||||

| Diameter | Flange | Screws | Weight (7,85 Kg/dm3) |

||||

| k | D | b | d2 | Thread | Bolt holes | KG | |

| 15 | 55 | 80 | 12 | 11 | M10 | 4 | 0,438 |

| 20 | 65 | 90 | 14 | 11 | M10 | 4 | 0,657 |

| 25 | 75 | 100 | 14 | 11 | M10 | 4 | 0,821 |

| 32 | 90 | 120 | 14 | 14 | M12 | 4 | 1,180 |

| 40 | 100 | 130 | 14 | 14 | M12 | 4 | 1,390 |

| 50 | 110 | 140 | 14 | 14 | M12 | 4 | 1,620 |

| 65 | 130 | 160 | 14 | 14 | M12 | 4 | 2,140 |

| 80 | 150 | 190 | 16 | 18 | M16 | 4 | 3,430 |

| 100 | 170 | 210 | 16 | 18 | M16 | 4 | 4,220 |

| 125 | 200 | 240 | 18 | 18 | M16 | 8 | 6,100 |

| 150 | 225 | 265 | 18 | 18 | M16 | 8 | 7,510 |

| 200 | 280 | 320 | 20 | 18 | M16 | 8 | 12,300 |

| 250 | 335 | 375 | 22 | 18 | M16 | 12 | 18,500 |

| 300 | 395 | 440 | 22 | 22 | M20 | 12 | 25,500 |

| 350 | 445 | 490 | 22 | 22 | M20 | 12 | 31,800 |

| 400 | 495 | 540 | 22 | 22 | M20 | 16 | 38,500 |

| 450 | 550 | 595 | 24 | 22 | M20 | 16 | 51,200 |

| 500 | 600 | 645 | 24 | 22 | M20 | 20 | 60,100 |

| 600 | 705 | 755 | 30 | 26 | M24 | 20 | 103,000 |

| 700 | 810 | 860 | 40 | 26 | M24 | 24 | 178,000 |

| 800 | 920 | 975 | 44 | 30 | M27 | 24 | 252,000 |

| 900 | 1020 | 1075 | 48 | 30 | M27 | 24 | 336,000 |

| 1000 | 1120 | 1175 | 52 | 30 | M27 | 28 | 435,000 |

| 1200 | 1340 | 1405 | 60 | 33 | M30 | 32 | 717,000 |

| 1400 | 1560 | 1630 | 68 | 36 | M33 | 36 | 1.094,000 |

| 1600 | 1760 | 1830 | 76 | 36 | M33 | 40 | 1.545,000 |

| 1800 | 1970 | 2045 | 84 | 39 | M36 | 44 | 2.131,000 |

| 2000 | 2180 | 2265 | 92 | 42 | M39 | 48 | 2.862,000 |

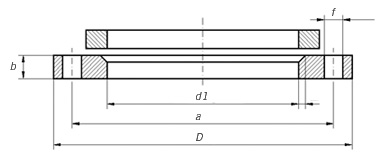

EN 1092 1 Threaded pn6 Flange Dimensions

| EN 1092-1 TYPE 13 PN6 THREADED FLANGE | |||||||||||||

| Rated Diameter | Flange | Neck | Raised face | Screws |

Weight |

||||||||

| d1 | Thread | k | D | b | h1 | d3 | d4 | f | d2 | Thread | Bolt holes | KG | |

| 15 | 21,3 | R 1/2″ | 55 | 80 | 12 | 20 | 30,0 | 40,0 | 2,0 | 11 | M10 | 4 | 0,373 |

| 20 | 26,9 | R 3/4″ | 65 | 90 | 14 | 24 | 40,0 | 50,0 | 2,0 | 11 | M10 | 4 | 0,584 |

| 25 | 33,7 | R 1″ | 75 | 100 | 14 | 24 | 50,0 | 60,0 | 2,0 | 11 | M10 | 4 | 0,729 |

| 32 | 42,4 | R 1-1/4″ | 90 | 120 | 14 | 26 | 60,0 | 70,0 | 2,0 | 14 | M12 | 4 | 1,040 |

| 40 | 48,3 | R 1-1/2″ | 100 | 130 | 14 | 26 | 70,0 | 80,0 | 3,0 | 14 | M12 | 4 | 1,200 |

| 50 | 60,3 | R 2″ | 110 | 140 | 14 | 28 | 80,0 | 90,0 | 3,0 | 14 | M12 | 4 | 1,340 |

| 65 | 76,1 | R 2-1/2″ | 130 | 160 | 14 | 32 | 100,0 | 110,0 | 3,0 | 14 | M12 | 4 | 1,830 |

| 80 | 88,9 | R 3″ | 150 | 190 | 16 | 34 | 110,0 | 128,0 | 3,0 | 18 | M16 | 4 | 2,750 |

| 100 | 114,3 | R 4″ | 170 | 210 | 16 | 40 | 130,0 | 148,0 | 3,0 | 18 | M16 | 4 | 3,010 |

| 125 | 139,7 | R 5″ | 200 | 240 | 18 | 44 | 160,0 | 178,0 | 3,0 | 18 | M16 | 8 | 4,300 |

| 150 | 168,3 | R 6″ | 225 | 265 | 18 | 44 | 185,0 | 202,0 | 3,0 | 18 | M16 | 8 | 4,630 |

Flanges Types and Standards

Slip-on Flanges

Slip-on Flanges, ASME B16.5 SOFF Flange, ASME B16.47 SORF Flange, SO Flange

Weld Neck Flanges

Weld Neck Flanges, ASME B16.5 WNFF Flange, ASME B16.47 WNRF Flange, WN Flange

Blind Flanges

Blind Flanges, ASME B16.5 BLFF Flange, ASME B16.47 BLRF Flange

Socket Weld Flanges

Socket Weld Flanges, ASME B16.5 SWRF Flange, ASME B16.47 Socket Weld Flange

Orifice Flanges

Orifice Flanges, ASME B16.36 Raised Face & Flat Face Orifice Flange

Threaded Flanges

Threaded Flanges, ASME B16.5 / B16.47 Raised Face & Flat Face Threaded Flange

Lap Joint Flanges

Lap Joint Flanges, ASME B16.5 / ASME B16.47 Loose Flange

Spectacle Blind Flanges

Spectacle Blind Flanges, ASME B16.5 / ASME B16.47 Spectacle Blind Flange

Ring Type Joint Flanges

Ring Type Joint Flanges, ASME B16.5 / ASME B16.47 RTJ Flange

Forged Flanges

Forged Flanges, ASME B16.5 / ASME B16.47 Forged Flange

ANSI Flanges

ANSI Flanges, ANSI Flange Dimensions in MM

ANSI/ASME B16.5 Flanges

ANSI B16.5 Flanges, ASME B16.5 Flanges Dimensions

ANSI/ASME B16.47 Flanges

ANSI B16.47 Flanges, ASME B16.47 Flanges Dimensions

API Flanges

API Flanges, API Flange Dimensions

BS Flanges

BS 4504, BS 10 Table D, BS 10 Table E, BS 10 Table F Flanges

DIN Flanges

DIN Flanges, DIN PN6 PN10 PN16 PN25 PN40 Flange

EN 1092-1 Flanges

EN 1092-1 Type 01, EN 1092-1 Type 02, EN 1092-1 Type 05, EN 1092-1 Type 11, EN 1092-1 Type 13

JIS Flanges

JIS B2220 5K 10K 16K 20K 30K 40K Flanges

GOST Standard Flanges

GOST / ГОСТ 12820-80 Flange, GOST / ГОСТ 12821-80 Flange

AWWA Standard Flanges

AWWA C207 Flanges, AWWA Class D Flange, AWWA Class E Flange, AWWA Class B Flange

Note: Prices are based on product, material grade, and quantity. Contact us anytime to get full quotation.

EN 1092-1 Flange Applications & Industries

We are well-known prestigious Manufacturers, Exporters, and Suppliers of high quality EN 1092-1 Type 01 Flanges. We supply EN 1092-1 Type 02 Flanges to customers in various industries including chemical, pharmaceutical, petrochemical, power, engineering and various other industrial applications. Test Certificate as per EN 10204 / 3.1B, Raw Materials Certificate, Third Party Inspection Report and 100% Radiography Test Report.

Ready Stock of EN 1092-1 Flange Export to

AFRICA: Algeria, Angola, Egypt, Equatorial Guinea, Gabon, Libya, Nigeria, South Africa, Sudan, The Republic Of Congo.

EUROPE: Albania, Austria, Belgium, Croatia, Czech Republic, Finland, France, Germany, Greece, Hungary, Ireland, Italy, Malta, Netherlands, Norway, Portugal, Russia, Slovakia, Slovenia, Spain, Switzerland, UK, Ukraine.

NORTH AMERICA: Costa Rica, Bahamas, Canada,Denmark, Jamaica, Mexico, Panama, Trinidad And Tobago, Puerto Rico, USA.

SOUTH AMERICA: Argentina, Bolivia, Brazil, Chile, Colombia, Ecuador, Guyana, Paraguay, Uruguay, Venezuela.

MIDDLE EAST: Bahrain, Cyprus, Iran, Iraq, Jordan, Kuwait, Oman, Qatar, Saudi Arabia (KSA), Syria, Turkey, United Arab Emirates (UAE), Yemen.

EN 1092-1 Flange Supplier

Please send us the complete details of EN 1092-1 Type 05 Flanges requirement. We offer EN 1092-1 Type 11 Flanges, and EN 1092-1 Type 13 Flanges which are accurately designed to provide satisfaction to our customers. We are assisted by a team of skilled professionals, who support us in all our career activities right from a realization of raw material to testing and final dispatch of these Class 150#, 300#, 400#, 600#, 900#, 1500#, 2500#, EN 1092-1 Flanges at our valuable customers end. Buy EN 1092-1 Plate PN16 Flangeat a cheap price from us.

sales@metalfed.com | +91 9137898594 | Quotation Form | Reach Us

Venezuela

Venezuela Myanmar

Myanmar Sri Lanka

Sri Lanka Belgium

Belgium Czechia

Czechia Greece

Greece Mexico

Mexico Tobago

Tobago Brazil

Brazil Chile

Chile France

France Colombia

Colombia South Africa

South Africa Jordan

Jordan Spain

Spain Hong Kong

Hong Kong Netherlands

Netherlands Poland

Poland Bangladesh

Bangladesh Indonesia

Indonesia Taiwan

Taiwan Nigeria

Nigeria Iraq

Iraq Ukraine

Ukraine Romania

Romania Cyprus

Cyprus Angola

Angola Norway

Norway USA

USA Saudi Arabia

Saudi Arabia Kuwait

Kuwait Thailand

Thailand South Korea

South Korea Singapore

Singapore Malaysia

Malaysia UAE

UAE Germany

Germany Italy

Italy Costa Rica

Costa Rica Kazakhstan

Kazakhstan Philippines

Philippines China

China UK

UK India

India Japan

Japan Russia

Russia Canada

Canada Iran

Iran Turkey

Turkey Morocco

Morocco Egypt

Egypt Vietnam

Vietnam Oman

Oman Australia

Australia Qatar

Qatar Portugal

Portugal